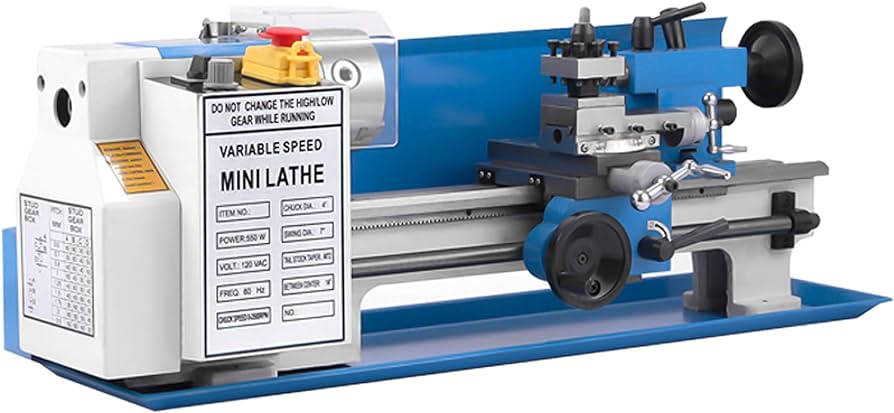

So, you’ve decided to take up woodworking and invest in a wood lathe – fantastic choice! Now, the next important step is equipping yourself with the right tools to make the most out of your new hobby. In this article, we will explore the essential tools you’ll need for your wood lathe, ensuring that you have everything necessary to unleash your creativity and bring your woodworking projects to life. Whether you’re a beginner or an experienced woodturner, let’s discover the must-have tools that will help you master the art of wood lathe craftsmanship.

Safety Equipment

Eye Protection

When working with a wood lathe, it is crucial to prioritize your safety, and one of the most important aspects is protecting your eyes. While turning wood, there is always a risk of wood chips or debris flying towards your face. To prevent any potential eye injuries, it is recommended to wear safety goggles or a face shield. These protective gears will ensure that your eyes are shielded from any flying particles, wood chips, or dust that may be generated during the turning process.

Hearing Protection

Woodturning can be a noisy process, especially when using large and powerful lathes. Continuous exposure to such noise can damage your hearing over time. To safeguard your hearing, it is highly recommended to wear hearing protection, such as earplugs or earmuffs. These protective equipment will help reduce the noise level and prevent any long-term hearing damage, enabling you to enjoy your woodworking hobby without compromising your well-being.

Dust Mask

Woodworking, including lathe turning, often generates a significant amount of dust and fine particles. Breathing in these particles can be harmful to your respiratory system. To minimize the intake of dust and protect your respiratory health, wearing a dust mask or respirator is essential. These masks are designed to filter out the fine particles and ensure that the air you breathe is clean and safe. Prioritizing your respiratory well-being by wearing a dust mask will make your woodturning experience much more enjoyable and worry-free.

Protective Clothing

While operating a wood lathe, it is advisable to wear appropriate protective clothing. Loose or dangling clothing can easily get caught in the lathe’s moving parts, leading to accidents or injuries. To minimize the risk, wear fitted and non-loose clothing, preferably made of thick fabric, such as denim. Additionally, avoid wearing jewelry or loose accessories that could pose a risk. By dressing appropriately for woodturning, you can ensure your safety and focus on creating beautiful pieces without any unnecessary hazards.

Lathe Stand or Bench

Having a stable and secure work area is crucial for a safe woodturning experience. A dedicated lathe stand or bench provides a sturdy and level surface for your lathe, ensuring stability while you work. This is essential to minimize any wobbling or movement of the lathe during operation, preventing accidents or mishaps. Investing in a reliable lathe stand or bench will not only enhance your safety but also contribute to smoother turning and greater precision. Remember, a stable work area is the foundation for a safe and enjoyable wood lathe experience.

Cutting Tools

Gouges

Gouges are a fundamental tool in woodturning and are available in various shapes and sizes. They are essential for removing large amounts of wood quickly and efficiently. The two most common types of gouges are the bowl gouge and spindle gouge. Bowl gouges have a deeper flute and are predominantly used for shaping the inside of bowls and hollow forms. On the other hand, spindle gouges have a shallower flute and are primarily used for shaping spindles and turning between centers. Investing in a good set of gouges will provide you with the versatility and cutting precision required for a wide range of woodturning projects.

Skew Chisels

Skew chisels are another indispensable tool in wood lathe turning. They are characterized by their flat, beveled edge and narrow profile. Skew chisels are primarily used for smooth finishing cuts, creating straight edges, and producing ornamental details. Additionally, they can also be used for planing cuts, creating convex or concave surfaces, and even for parting off workpieces. It is essential to practice proper technique and maintain a sharp edge on your skew chisel to achieve precise and smooth cuts. Including a few skew chisels of varying sizes in your tool collection will greatly enhance your woodturning capabilities.

Parting Tools

Parting tools, as the name suggests, are utilized for separating a workpiece from the main body or for creating grooves and recesses. They have a thick, straight blade that allows for clean and accurate parting-off operations. Parting tools come in various widths to accommodate different workpiece sizes and depths. Whether you are creating a tenon, forming a decorative groove, or neatly cutting your finished piece from the lathe, having a reliable parting tool is crucial for achieving professional-looking results.

Bowl Gouges

As mentioned earlier, bowl gouges play a vital role in woodturning specifically focused on bowls and vessel forms. They have larger and deeper flutes compared to spindle gouges, allowing for efficient wood removal when shaping the interior of a bowl. Bowl gouges are available in different shapes and sizes, each with its own unique characteristics and cutting abilities. Investing in high-quality bowl gouges, combined with proper sharpening techniques, will enable you to transform chunks of wood into stunning and elegant bowls.

Scrapers

Scrapers are versatile tools that come in various shapes and sizes, allowing you to achieve different cutting profiles and finishes. They are primarily used for finishing cuts, refining curves, and achieving clean surfaces on both spindle and bowl work. Scrapers work by scraping rather than cutting, creating smooth surfaces with minimal tear-out. They are especially useful for refining the exterior of bowls, removing tool marks, and achieving intricate details. Adding a selection of scrapers to your collection will provide you with the necessary tools to achieve the desired finish on your woodturned pieces.

Sharpening and Honing Equipment

Grinder

A grinder is an essential tool for maintaining the sharpness of your woodturning tools. It is used to remove metal from the tool’s bevel to create or restore a sharp cutting edge. A bench grinder with a suitable grinding wheel is a common choice for sharpening woodturning tools. However, it is important to remember that grinding generates heat that can potentially damage the tool’s temper. To prevent overheating, it is recommended to frequently cool the tool by dipping it in water during the grinding process. By investing in a grinder and learning proper sharpening techniques, you can ensure that your cutting tools are always sharp and ready for use.

Sharpening Jigs

Sharpening jigs are valuable accessories that assist in maintaining consistent bevel angles and precise grinding of your woodturning tools. These jigs ensure that you achieve accurate cutting edges with repeated sharpening, enhancing the performance and longevity of your tools. There are various types of sharpening jigs available, including platform jigs and angle-setting jigs. By utilizing these jigs, you can simplify and streamline the sharpening process, making it easier to maintain optimal cutting performance.

Honers

Honing tools are crucial for refining and polishing the cutting edges of your woodturning tools. By removing any burrs or imperfections left after grinding, honers help create a sharp and smooth cutting surface. Honing can be done manually using sharpening stones or honing guides, or with the assistance of a honing machine. Whichever method you choose, regularly honing your woodturning tools will ensure that they remain in optimal cutting condition, resulting in cleaner cuts and enhanced precision.

Diamond Stones or Hones

Diamond stones or hones are an excellent addition to your sharpening arsenal, as they provide a fast and efficient way to sharpen your woodturning tools. These stones or hones consist of a diamond-coated surface that quickly removes material while maintaining a flat and even profile. Diamond stones or hones are highly durable and can withstand prolonged use without losing their effectiveness. Incorporating diamond stones or hones into your sharpening routine will significantly reduce the time it takes to achieve razor-sharp edges on your tools.

Stropping Materials

Stropping is a final step in sharpening that helps refine and polish the cutting edge of your woodturning tools. Stropping involves dragging the tool’s bevel along a leather or fabric surface coated with a polishing compound. This process removes any remaining burrs or microscopic imperfections, resulting in an incredibly sharp cutting edge. Stropping materials, such as leather strops or honing compounds, are readily available and easy to use. By including stropping in your sharpening routine, you can achieve exceptional cutting performance and extend the life of your woodturning tools.

Measuring and Layout Tools

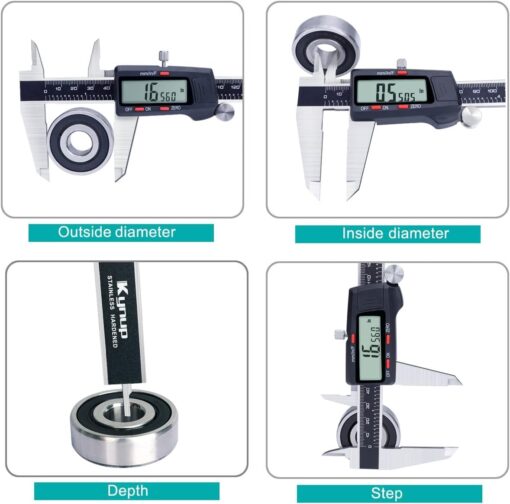

Calipers

Calipers are precision measuring tools that enable you to measure and mark specific dimensions accurately. They consist of two adjustable legs that can be locked in place to secure a measurement. Calipers are primarily used to measure diameters, depths, and distances on your workpiece. These measurements are essential for achieving precise dimensions and ensuring symmetrical turnings. Whether you are measuring the thickness of a spindle or the depth of a bowl, having a reliable set of calipers will greatly enhance your accuracy and overall craftsmanship.

Depth Gauges

Depth gauges are specialized measuring tools used to measure the depth of holes, grooves, or recesses. They are invaluable when turning bowls or creating intricate details that require precise depth measurements. Some depth gauges come equipped with a depth stop, allowing you to set a desired depth and achieve consistency across multiple pieces. By utilizing a depth gauge, you can ensure that you achieve consistent and accurate depths in your woodturning projects.

Dial Indicators

Dial indicators are precision measuring devices that are commonly used in metalworking but can also be employed in wood lathe turning. These instruments provide accurate readings of small distances or changes in position. Dial indicators are particularly useful for measuring runout or vibrations in the lathe’s spindle and ensuring that your workpiece is rotating true. By utilizing dial indicators in your woodturning setup, you can identify and correct any deviations or irregularities, resulting in smoother and more precise turnings.

Marking Tools

Marking tools are essential for laying out designs, patterns, or measurements on your workpiece before turning. They enable you to mark reference points, outline details, or indicate areas for cutting or shaping. Popular marking tools for woodturning include pencils, marking knives, and awls. These tools allow you to transfer your design or measurements accurately onto the wood, ensuring that you achieve the desired outcome. By using marking tools effectively, you can enhance your precision and achieve consistent and symmetrical turnings.

Center Finder

A center finder is a useful tool for locating the center of your workpiece, which is essential for achieving accurate and balanced turnings. Center finders typically consist of several concentric circles or lines that can be aligned with the edges of your workpiece. By rotating the center finder, you can determine the exact center point, enabling you to mount the workpiece securely on your lathe. Center finders eliminate guesswork and ensure that your woodturnings are centered and well-balanced, resulting in visually appealing and structurally sound pieces.