So, you’ve heard about SDS drills but you’re not exactly sure what they are or how they work. Well, fear not friend, because in this article, we’re going to break it down for you. An SDS drill is a specialized power tool that allows you to easily drill into hard materials such as concrete, brick, and stone. It’s designed to provide extra power and versatility, making it a must-have tool for any DIY enthusiast or professional tradesperson. Whether you’re looking to hang shelves or create larger holes for plumbing or electrical work, an SDS drill will be your trusty companion in getting the job done efficiently and effectively. An SDS drill, also known as a Special Direct System drill, is a versatile and powerful tool used for various drilling and chiseling tasks. It has gained popularity among professionals and DIY enthusiasts due to its unique design and functionality. In this article, we will explore the definition, design, types, advantages, limitations, applications, and safety precautions of SDS drills. Additionally, we will provide tips on choosing the right SDS drill and maintaining it for optimal performance.

Definition

An SDS drill is a type of rotary hammer drill that utilizes a specific chuck system called SDS, which stands for Slotted Drive System or Slotted Drive Shaft. This chuck system allows for quick and effortless changing of drill bits and chisels. The SDS drill’s primary function is to drill holes in various materials such as concrete, masonry, metal, and wood. It can also be used for chiseling tasks, making it a versatile tool for construction, renovation, and other related projects.

Design and Functionality

The design of an SDS drill is what sets it apart from conventional drills. It features a special SDS chuck system, which consists of grooves on the shank of the drill bit or chisel and corresponding ball bearings inside the drill’s chuck. This design ensures a secure and tight connection between the drill bit or chisel and the drill, eliminating the risk of slippage or dislodgment during operation. It also allows for effortless and quick bit changes, saving valuable time and effort.

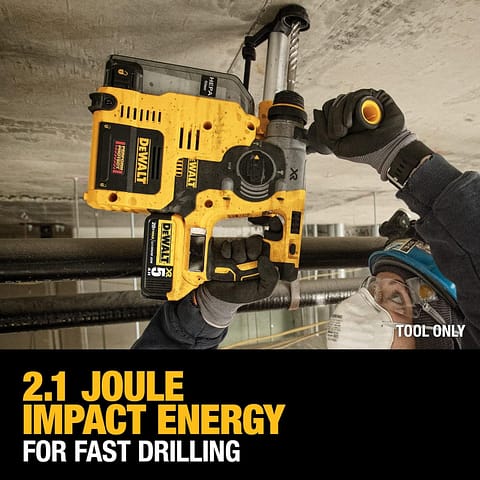

Furthermore, SDS drills are equipped with a pneumatic hammering mechanism, also known as a hammer action. This mechanism enables the drill to apply a forward and backward hammering motion while rotating, providing enhanced drilling power and efficiency. The hammer action significantly reduces the physical effort required for drilling into hard materials, making it a preferred choice among professionals and individuals working on demanding projects.

Types of SDS Drills

There are three main types of SDS drills available in the market: SDS-Plus, SDS-Max, and SDS-Top. These types differ in terms of their chuck size, power capability, and application range.

- SDS-Plus: The SDS-Plus drill is the most common and widely used type among the three. It features a 10 mm chuck, making it suitable for drilling holes up to 26 mm in diameter. This type of SDS drill is ideal for small to medium-sized drilling tasks and is commonly used in construction, woodworking, and electrical installations.

- SDS-Max: The SDS-Max drill is more robust and powerful than the SDS-Plus. It has a larger chuck size of 18 mm and can drill larger holes, up to 50 mm in diameter. This type of SDS drill is commonly used in heavy-duty applications such as construction, demolition, and digging through thick concrete or masonry.

- SDS-Top: The SDS-Top drill, also known as SDS Special, is less common and mainly used for specific applications. It features a triangular-shaped chuck and is designed for heavy-duty drilling and chiseling tasks. The SDS-Top drill is often used in specialized industries such as mining, tunneling, and foundation work.

Advantages of SDS Drills

Using an SDS drill offers several advantages over conventional drills. Firstly, the SDS chuck system provides a secure and stable connection between the drill bit or chisel and the drill, minimizing the risk of accidents caused by slippage or dislodgment. This feature ensures precise and efficient drilling, making it a reliable tool for professionals who require accuracy in their work.

Moreover, the hammer action mechanism incorporated in SDS drills significantly reduces the physical effort required for drilling into hard materials such as concrete or masonry. The hammering motion helps break through tough surfaces, allowing for faster drilling and increased productivity. This feature is particularly beneficial in projects that involve extensive drilling or chiseling, as it reduces operator fatigue and strain.

Another advantage of SDS drills is their versatility. With the ability to change bits and chisels quickly, these drills can accommodate various tasks, including drilling holes of different sizes and chiseling away unwanted materials. This versatility eliminates the need for multiple tools, saving both time and money for users.

Limitations of SDS Drills

While SDS drills offer numerous advantages, they do have a few limitations to consider. One limitation is the size and weight of the drill. SDS drills tend to be bulkier and heavier than traditional drills due to the incorporation of the hammering mechanism. This can be challenging for users who prioritize portability or have limited physical strength.

Additionally, SDS drills may have limited application in certain materials. While they excel in drilling through concrete, masonry, and other hard materials, they may not perform as efficiently on softer materials like wood or plastic. The hammer action can be too aggressive, potentially causing damage or creating rough holes in these softer materials.

Another limitation is the higher cost associated with SDS drills compared to conventional drills. Due to their specialized design and functionality, SDS drills tend to be more expensive, making them less accessible for individuals on a tight budget. However, considering their enhanced performance and versatility, the cost difference may be justified for those who require the capabilities of an SDS drill.

Applications of SDS Drills

SDS drills find applications in numerous industries and projects. In the construction industry, they are widely used for drilling holes in concrete or masonry walls for electrical wiring, plumbing, or anchor installation. They are also essential for professionals involved in renovations or repairs, as they can efficiently remove old tiles, chisel away concrete, or create slots for door hinges.

Furthermore, SDS drills are valuable tools in woodworking tasks, allowing for precise drilling and dowel hole creation. They can also be utilized for metalworking or automotive projects, where drilling into metal surfaces is required. In summary, SDS drills are versatile tools suitable for a wide range of applications, making them indispensable for professionals and individuals alike.

Choosing the Right SDS Drill

When choosing an SDS drill, several factors should be considered to ensure it meets your specific requirements. Firstly, determine the intended application and the materials you will be working with. This will help determine the appropriate chuck size and power capability needed for your projects.

Secondly, consider the ergonomics of the drill. Ensure that the handle is comfortable to grip, and the weight is manageable for extended periods of use. This is especially important for individuals who may have physical limitations or prioritize user comfort.

Lastly, take into account the brand reputation and customer reviews. Opting for a reliable and reputable brand ensures a higher likelihood of product quality and after-sales support. Reading customer reviews can provide valuable insights into the drill’s performance, durability, and overall user satisfaction.

Safety Precautions for Using SDS Drills

While SDS drills are powerful tools, they can pose risks if not used properly. It is crucial to follow safety precautions to prevent accidents and injuries. Here are some essential safety guidelines to keep in mind:

- Read and understand the manufacturer’s instructions before using the SDS drill. Familiarize yourself with the tool’s features, capabilities, and limitations.

- Wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and ear protection to safeguard yourself from flying debris, vibration, and noise.

- Ensure a stable work area by securing the material to be drilled or chiseled. This prevents unexpected movement or slippage, reducing the risk of accidents.

- Do not overload the SDS drill by applying excessive force or pushing the drill beyond its recommended limits. This can cause overheating, damage to the tool, or potential injury to the operator.

- Before starting the drilling or chiseling task, inspect the drill, chuck, and drill bits for any signs of damage or wear. Replace any worn-out or damaged parts to ensure safe and efficient operation.

- When changing drill bits or chisels, always disconnect the power source and wait for the drill to come to a complete stop. Use appropriate tools and follow the manufacturer’s instructions for safe bit changes.

- Store the SDS drill in a secure and dry location, away from children and unauthorized users. Regularly inspect and maintain the tool to ensure its optimal performance and longevity.

Remember, safety should always be the top priority when using any power tool, including the SDS drill. By following these safety precautions, you can ensure a safe working environment and maximize your productivity.

Maintenance and Care of SDS Drills

Proper maintenance and care are essential for the longevity and optimal performance of SDS drills. Here are some maintenance tips to keep your drill in good condition:

- Regularly clean the drill chuck and bit shank to remove any debris, dust, or residue that may accumulate during use. This ensures a secure connection and prevents potential slippage or dislodgment.

- Lubricate the chuck system and moving parts of the drill as recommended by the manufacturer. This helps reduce friction and wear, prolonging the lifespan of the drill.

- Inspect the power cord for any signs of damage, fraying, or exposed wires. If any issues are detected, replace the power cord immediately to avoid electrical hazards.

- Check the carbon brushes regularly and replace them if they are worn out. Carbon brushes play a crucial role in delivering power to the drill’s motor, and worn-out brushes can affect the drill’s performance.

- Store the SDS drill in a dry and dust-free environment to prevent corrosion and damage. Consider using a protective case or box to keep the drill and its accessories organized and protected.

- Regularly check the battery (if applicable) and recharge it as needed. Follow the manufacturer’s recommendations for battery maintenance to ensure maximum battery life and performance.

Remember to consult the drill’s user manual for specific maintenance instructions and intervals. Proper maintenance not only extends the lifespan of the drill but also ensures safe and efficient operation.

Conclusion

In conclusion, an SDS drill is a versatile and powerful tool that offers numerous advantages in drilling and chiseling tasks. Its unique design, incorporating the SDS chuck system and hammer action mechanism, provides secure connections, enhanced drilling power, and quick bit changes. SDS drills find applications in construction, woodworking, metalworking, and other industries.

When choosing an SDS drill, consider factors such as chuck size, power capability, ergonomics, and brand reputation. Follow safety precautions to prevent accidents and injuries, and maintain the drill regularly for optimal performance. By understanding the features, limitations, and maintenance requirements of an SDS drill, you can make the most out of this valuable tool and accomplish your projects efficiently and safely.