So, you’ve come across the term “oscillating multi-tool?” and you’re wondering what it’s all about. Well, allow us to shed some light on this versatile tool that has been revolutionizing DIY projects and professional handyman tasks alike. An oscillating multi-tool, simply put, is a compact and powerful device that oscillates rapidly in a back-and-forth motion, enabling it to tackle a wide range of cutting, sanding, scraping, and grinding applications with precision and ease. Whether you’re a seasond DIY enthusiast or just starting out in the world of home improvement, understanding the wonders of an oscillating multi-tool is sure to elevate your toolbox to new heights.

What Is an Oscillating Multi-tool?

An oscillating multi-tool is a versatile and powerful handheld tool that is used for various tasks such as cutting, sanding, scraping, grinding, and polishing. It is designed to provide precise and efficient performance in a wide range of applications and has become a popular choice among DIY enthusiasts, professionals, and craftsmen. With its unique oscillating motion, this tool offers incredible versatility, accessibility, and ease of use, making it an essential addition to any tool collection.

Definition

An oscillating multi-tool is defined as a handheld power tool that operates by oscillating the blade or accessory back and forth at high speed. This oscillating motion is what sets this tool apart from other power tools, as it allows for precise cutting, sanding, scraping, and other functions. The tool typically features a motor, oscillating mechanism, blade mounting system, handle/grip, speed control, and accessory attachment, which work together to provide users with a versatile and efficient tool.

Explanation

The oscillating motion of the tool creates a unique cutting action that is ideal for detailed and intricate tasks. Unlike other power tools that rotate or reciprocate, the oscillating multi-tool moves the blade or accessory in a side-to-side motion, resulting in minimal kickback and increased control. This makes it an excellent choice for working in tight spaces, corners, and hard-to-reach areas.

Versatility

One of the primary reasons why the oscillating multi-tool has gained immense popularity is its versatility. With the ability to change blades and attachments, this tool can perform a wide range of functions, including cutting, sanding, scraping, grinding, polishing, grout removal, plunge cutting, flush cutting, flush sanding, and precision jobs. Whether you need to make precise cuts in wood, remove paint from a door, or sand hard-to-reach areas, the oscillating multi-tool is up to the task.

Functions

The oscillating multi-tool is a multi-functional tool that can perform a variety of tasks. Here are some of the key functions it excels at:

Cutting

The oscillating multi-tool is capable of making precise cuts in a variety of materials, including wood, metal, plastic, drywall, and more. With the right blade, you can easily cut through different thicknesses and shapes with ease.

Sanding

The tool’s oscillating motion, coupled with sanding pads or discs, allows for efficient sanding of both flat and curved surfaces. It is perfect for removing old finishes, smoothing rough edges, and preparing surfaces for painting or refinishing.

Scraping

The oscillating multi-tool is highly effective for scraping off old paint, adhesive, and caulk. With a scraping blade attachment, you can remove stubborn materials without damaging the underlying surface.

Grinding

With the appropriate grinding blade, an oscillating multi-tool can grind and shape various materials, such as metal, stone, and concrete. It is useful for tasks such as sharpening blades, removing excess material, or shaping edges.

Polishing

The oscillating multi-tool can be transformed into a polishing tool by attaching a polishing pad or disc. It is ideal for achieving a smooth and glossy finish on surfaces, including metals, plastics, and even car surfaces.

Grout Removal

When equipped with a grout removal blade, the oscillating multi-tool can quickly and easily remove old and worn-out grout from between tiles without damaging the surrounding tiles.

Plunge Cutting

The oscillating multi-tool’s ability to make precise plunge cuts makes it ideal for tasks such as cutting holes in drywall, making notches in wood, or creating openings in various materials.

Flush Cutting

The tool’s ability to cut flush with a surface is perfect for trimming protruding materials, such as nails, screws, or pipe ends. It provides a neat and precise cut without damaging the surrounding area.

Flush Sanding

The oscillating multi-tool’s flush sanding feature allows for sanding in tight corners and hard-to-reach areas. It ensures a smooth and even finish on surfaces that are difficult to sand using traditional sanding methods.

Precision Jobs

Due to its maneuverability and oscillating motion, the multi-tool is an excellent choice for precision tasks, such as cutting intricate patterns, making fine adjustments, or working on delicate materials.

Components

An oscillating multi-tool consists of several key components that work together to provide efficient and reliable performance. Here are the main components of an oscillating multi-tool:

Motor

The motor is the heart of the oscillating multi-tool, providing the power needed to drive the oscillating mechanism and the various attachments. It is essential to choose a tool with a powerful motor that can handle the demands of different tasks.

Oscillating Mechanism

The oscillating mechanism is responsible for converting the rotational motion from the motor into the back and forth oscillating motion of the blade or accessory. This mechanism ensures smooth and precise movement, allowing for accurate cutting and other functions.

Blade Mounting System

The blade mounting system is the mechanism that holds the blade or accessory securely in place. Most oscillating multi-tools use a quick-change blade mounting system, allowing for easy and tool-free blade changes.

Handle/Grip

The handle or grip is where the user holds the tool and provides control and stability during operation. A comfortable and ergonomic handle is essential for reducing fatigue and ensuring precise control over the oscillating multi-tool.

Speed Control

Most oscillating multi-tools feature variable speed control, allowing users to adjust the speed according to the task at hand. This feature is particularly useful when working with different materials or achieving different levels of precision.

Accessory Attachment

The accessory attachment mechanism allows for quick and secure attachment of various blades and accessories. It should be easy to use and hold the accessories firmly in place to ensure safety and efficiency during operation.

Power Source

Oscillating multi-tools are available in both corded and cordless models, each with its advantages and limitations. The power source is an important consideration when choosing the right tool for your needs.

Corded

Corded oscillating multi-tools are powered by electricity and require a power outlet for operation. They offer consistent power and do not require recharging. However, they are limited by the length of the cord, which may restrict mobility and accessibility.

Cordless

Cordless oscillating multi-tools are powered by rechargeable batteries, offering portability and freedom of movement. They are not limited by cords, allowing users to work in remote areas or when access to electricity is limited. However, cordless tools have a limited runtime and may require frequent battery recharging.

Battery Types

Cordless oscillating multi-tools often use lithium-ion batteries due to their high energy density, lightweight design, and lack of memory effect. Lithium-ion batteries provide longer runtimes and shorter charging times compared to traditional nickel-cadmium (Ni-Cd) batteries.

Runtime

The runtime of a cordless oscillating multi-tool depends on the battery capacity and the intensity of the task. Higher-capacity batteries provide longer runtimes, allowing for extended use before recharging is required. It is important to consider the runtime when evaluating the suitability of a cordless tool for your intended applications.

Charging Time

The charging time of cordless oscillating multi-tool batteries varies depending on the battery capacity and the charger’s capabilities. Fast chargers can significantly reduce charging time, allowing for minimal downtime between tasks. It is advisable to choose a tool with a charger that matches your needs.

Types of Blades

Different blades and accessories are available for oscillating multi-tools, each designed for specific tasks and materials. Understanding the types of blades available will allow you to select the most suitable one for your needs.

Cutting Blades

Cutting blades are the most commonly used blades for oscillating multi-tools. They come in various shapes and tooth configurations to suit different materials and cutting requirements. From general-purpose cutting blades for wood to metal-cutting blades and precision cutting blades, there is a cutting blade for every task.

Sanding Pads

Sanding pads or discs are used for sanding tasks, such as smoothing surfaces, removing finishes, or preparing surfaces for painting or refinishing. They come in different grits to achieve different levels of smoothness and can be easily attached and replaced.

Scraping Blades

Scraping blades are ideal for removing old paint, adhesive, caulk, or other materials from surfaces. They feature a flat edge or shaped profile for efficient and precise scraping, allowing you to remove materials without damaging the underlying surface.

Grinding Blades

Grinding blades are used for shaping and smoothing various materials, such as metal, stone, or concrete. They come in different shapes and sizes to accommodate different applications, including grinding, sharpening, and material removal.

Specialty Blades

There are also specialty blades available for specific tasks, such as grout removal blades for removing grout between tiles, plunge cutting blades for making precise cuts in materials, and flush-cutting blades for trimming protruding materials without damaging the surrounding area.

Applications

The versatility and functionality of oscillating multi-tools make them suitable for a wide range of applications across various industries. Here are some of the common applications where these tools excel:

Home Renovation

Oscillating multi-tools are invaluable during home renovation projects. They can be used for cutting baseboards, doorjambs, or trim, removing old paint or wallpaper, sanding uneven surfaces, or even installing new fixtures or hardware.

Construction

In construction applications, oscillating multi-tools are often used for tasks such as cutting pipes or tubing, removing grout, sanding rough surfaces, or making precise and quick cuts in construction materials.

Woodworking

Woodworkers find oscillating multi-tools extremely useful for tasks such as cutting intricate patterns, making notches or grooves, sanding wood surfaces, or removing old finishes. They offer precise control and great maneuverability, making them indispensable in any woodworking project.

Metalworking

Whether it’s cutting through metal sheets, removing rust or paint from metal surfaces, or shaping metal materials, oscillating multi-tools provide the precision and versatility required for metalworking tasks.

Automotive

From cutting through upholstery and carpet to sanding or polishing metal surfaces, oscillating multi-tools find their place in automotive applications. They help with tasks such as removing adhesive, shaping materials, or accessing hard-to-reach areas.

Plumbing

Oscillating multi-tools are widely used in plumbing applications, where they facilitate tasks like cutting pipes, removing old caulk or seals, or sanding plumbing fixtures. The ability to make precise and controlled cuts is particularly beneficial in plumbing installations or repairs.

Tile Installation

The ability to remove grout, make plunge cuts, and sand uneven surfaces makes oscillating multi-tools invaluable in tile installation projects. They provide accuracy and control when working with delicate tiles and intricate patterns.

Crafting

Crafters and hobbyists can leverage the versatility of oscillating multi-tools for various crafting projects. From cutting through different materials to sanding, scraping, or polishing, these tools enable precise and intricate work.

DIY Projects

Oscillating multi-tools are a go-to tool for DIY enthusiasts due to their versatility and ease of use. They can be used in a wide range of DIY projects, from furniture restoration and repair to home improvement tasks such as door installation or tile repairs.

Professional Use

Oscillating multi-tools are widely used by professionals across various industries, including carpenters, electricians, plumbers, remodelers, and more. Their versatility, precision, and efficiency make them an essential tool in professional toolboxes.

Advantages

Oscillating multi-tools offer numerous advantages that make them a popular choice among DIYers, professionals, and craftsmen alike. Some of the key advantages of these tools include:

Versatility

One of the most significant advantages of oscillating multi-tools is their versatility. With the ability to change blades and attachments, these tools can perform a wide range of tasks, eliminating the need for multiple specialized tools.

Precision

Oscillating multi-tools provide precise control and maneuverability, making them a preferred choice for intricate and detailed work. The oscillating motion allows for accurate cuts, refined sanding, and controlled scraping, ensuring professional results.

Ease of Use

These tools are designed with user-friendliness in mind. They feature ergonomic handles, intuitive controls, and tool-free blade changes, making them easy to operate, even for beginners. The oscillating motion also reduces kickback, improving safety and control.

Efficiency

The oscillating motion of these tools allows for efficient material removal. Whether it’s cutting through tough materials, sanding a large surface area, or scraping off stubborn adhesive, oscillating multi-tools can get the job done quickly and efficiently.

Accessibility

The compact size and shape of oscillating multi-tools make them highly accessible for tight spaces and hard-to-reach areas. Their ability to work in corners and close to edges ensures that no task is too challenging, even in cramped or obstructed spaces.

Time-saving

The versatility and efficiency of oscillating multi-tools translate into significant time savings. By eliminating the need for manual sanding, scraping, or using multiple tools for a single task, these tools allow users to complete projects faster and more efficiently.

Disadvantages

While oscillating multi-tools offer numerous advantages, it is important to consider their limitations. Here are some disadvantages associated with these tools:

Cost

High-quality oscillating multi-tools can be relatively expensive, especially when compared to single-function tools. However, considering the versatility and efficiency they offer, the investment can be worthwhile for those who require a wide range of capabilities.

Vibrations

Oscillating multi-tools can generate vibrations during operation, particularly when cutting, grinding, or using high-speed settings. Although manufacturers have improved vibration reduction technologies, prolonged use or improper technique may still cause hand fatigue.

Noise

Like most power tools, oscillating multi-tools produce noise during operation. While the noise level can vary depending on the model and brand, it is advisable to wear hearing protection, especially when using the tool for long periods or in noisy environments.

Dust

Certain applications, such as sanding or cutting through materials, can generate dust or debris. It is important to wear appropriate respiratory protection and take measures to minimize dust dispersion, such as using dust extraction attachments or working in a well-ventilated area.

Safety Concerns

As with any power tool, safety precautions should be taken when using an oscillating multi-tool. Always read and follow the manufacturer’s instructions, wear appropriate protective gear, secure the workpiece properly, and avoid using the tool in wet or hazardous conditions.

Popular Brands

There are several reputable brands that manufacture oscillating multi-tools, each offering their unique features and capabilities. Some of the popular brands include:

- Bosch: Known for their high-quality tools, Bosch offers a wide range of oscillating multi-tools that excel in performance, durability, and versatility.

- DeWalt: DeWalt is a trusted brand in the power tool industry, and their oscillating multi-tools are no exception. They offer robust and reliable tools suitable for both DIYers and professionals.

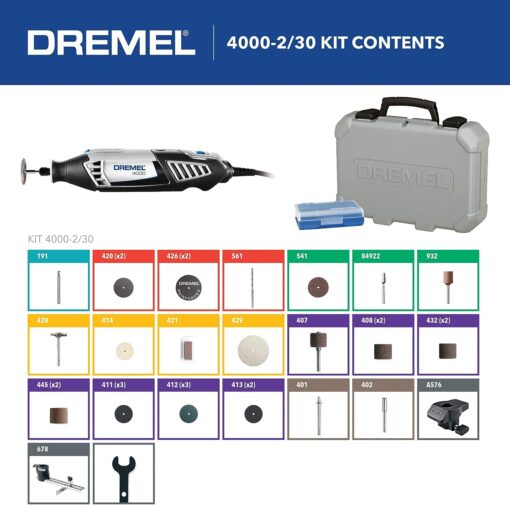

- Dremel: Dremel is well-known for their rotary tools, and they also offer a line of oscillating multi-tools. These tools are lightweight, compact, and perfect for detailed and precision work.

- Milwaukee: Milwaukee is a respected brand that produces a range of high-performance power tools. Their oscillating multi-tools offer exceptional power, control, and durability for professional use.

- Fein: Fein is often credited with inventing the oscillating tool, and their expertise in this area is evident in their high-quality tools. Fein oscillating multi-tools are known for their precision, performance, and longevity.

These brands have established themselves as leaders in the oscillating multi-tool market, providing users with reliable tools and accessories to tackle various applications.

Tips for Using an Oscillating Multi-tool

To make the most of your oscillating multi-tool, here are some helpful tips for safe and effective operation:

Appropriate Blade Selection

Choose the right blade for the task at hand. Different blades are designed for specific materials and functions, so selecting the appropriate blade will ensure optimal performance and longevity.

Safety Precautions

Always prioritize safety when using an oscillating multi-tool. Follow the manufacturer’s instructions, wear appropriate protective gear (such as safety glasses, gloves, and a dust mask), and avoid using the tool in hazardous conditions.

Securing Material

Properly secure the material you are working on to prevent movement or slipping, which can result in inaccurate cuts or potential hazards. Use clamps or other appropriate methods to ensure that the material remains steady during operation.

Maintaining Control

Maintain a firm grip on the tool and exercise control over its movement. Avoid excessive force or aggressive movements, as this may lead to loss of control or damage to the material.

Choosing the Right Speed

Adjust the speed of the oscillating multi-tool according to the material and task. Higher speeds are generally suited for cutting or grinding, while lower speeds are more suitable for precision tasks or finishing work.

Keeping the Work Area Clean

Keep the work area clean and free from debris to improve visibility and prevent damage to the tool or the material. Regularly remove dust, debris, or particles from the tool, as they can affect performance and longevity.

Proper Technique

Practice proper technique when operating the oscillating multi-tool. Learn how to control the tool’s movement, make smooth and steady cuts, and maintain a consistent sanding or scraping motion.

Wearing Protective Gear

Always wear appropriate protective gear, including safety glasses, gloves, and a dust mask. This will protect you from flying debris, potential hazards, and dust or particles generated during operation.

Understanding Material Compatibility

Different materials may require specific blades or accessories for optimal performance. Understand the compatibility of the tools and accessories with the materials you are working on to achieve the best results.

Practicing on Scrap Pieces

If you are new to using an oscillating multi-tool or trying a new technique, it is advisable to practice on scrap pieces of the same material before working on the actual project. This will allow you to familiarize yourself with the tool and ensure that you achieve the desired outcome.

In conclusion, an oscillating multi-tool is a versatile and indispensable tool that offers a wide range of functions and applications. Whether you are a DIY enthusiast, a professional tradesperson, or a hobbyist, an oscillating multi-tool can enhance your productivity, precision, and efficiency. With its ability to perform tasks such as cutting, sanding, scraping, and grinding, this tool provides an all-in-one solution for various projects. By understanding its components, power source options, blade types, applications, advantages, disadvantages, and tips for use, you can make an informed decision when choosing an oscillating multi-tool that meets your specific needs and requirements.