When searching for a power screwdriver or impact driver, it’s essential to look beyond appearances and consider the features that will truly enhance your DIY projects. From the torque settings to the battery life and even the grip, there are numerous aspects to weigh before making a purchase. By delving into the various features and understanding their significance, you can make an informed decision that aligns perfectly with your needs and ensures a seamless and efficient drilling experience every time.

1. Power Source

Type of Power Source

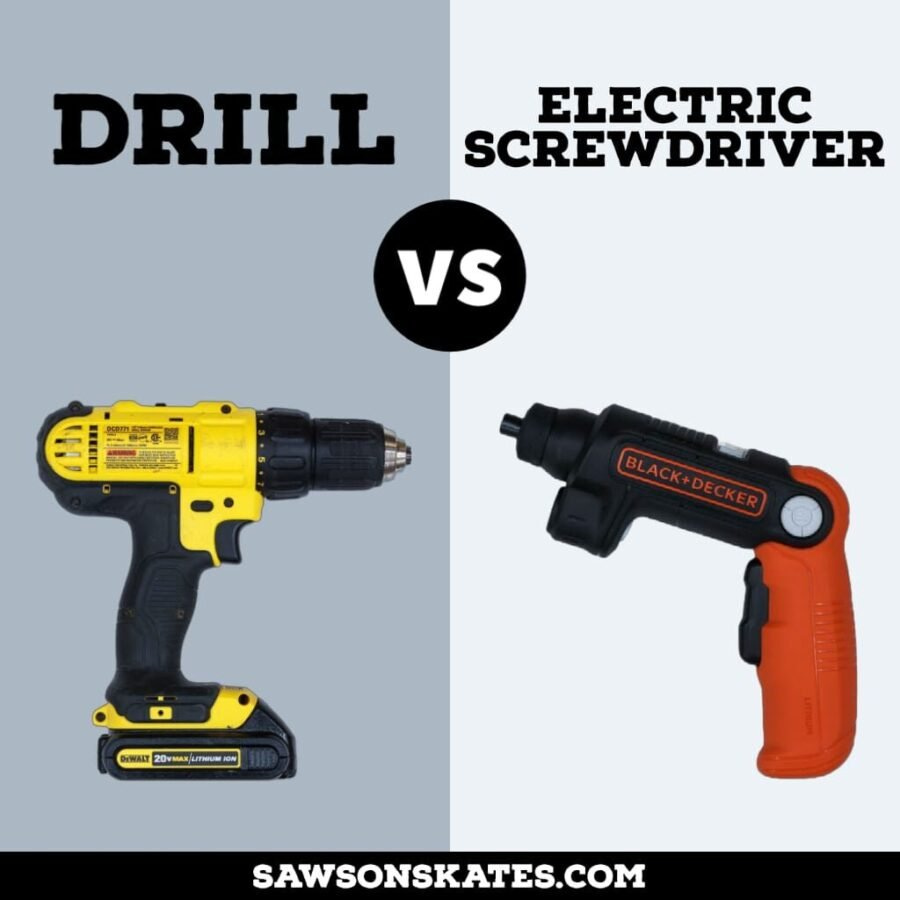

When choosing a power screwdriver or impact driver, one of the first things to consider is the type of power source it uses. Most models on the market today come in two options: corded or cordless. Corded power screwdrivers or impact drivers are powered by electricity and require an outlet for operation. On the other hand, cordless models are powered by rechargeable batteries, offering more freedom and portability.

Battery Voltage

For cordless power screwdrivers or impact drivers, the battery voltage is an essential factor to consider. Higher voltage batteries generally provide more power, allowing for faster and more efficient operation. However, it’s essential to strike a balance between power and overall weight, as higher voltage batteries tend to be bulkier and heavier.

Battery Type

In addition to battery voltage, it’s important to consider the type of battery used in the power screwdriver or impact driver. Lithium-ion (Li-ion) batteries are a popular choice due to their longer lifespan, quicker charging capabilities, and overall reliability. They also tend to be lighter, which enhances the overall portability of the tool.

Battery Life

Battery life is a crucial aspect to consider when purchasing a cordless power screwdriver or impact driver. It determines how long the tool can operate before requiring a recharge. Opting for a model with a longer battery life ensures uninterrupted work and reduces downtime for recharging. Look for specifications regarding battery life and ensure it meets your intended usage requirements.

2. Speed and Torque

Variable Speed Control

Variable speed control is a valuable feature in a power screwdriver or impact driver. It allows you to adjust the speed of the tool based on your needs, providing versatility and precision for different tasks. Whether you require a slow and controlled speed for delicate installations or a higher speed for quick and efficient work, having variable speed control is advantageous.

Maximum RPM

RPM, or rotations per minute, indicates the maximum speed at which the tool can operate. A higher RPM means faster driving or drilling capabilities. However, it’s important to note that different applications may require varying RPMs. For example, tasks involving more delicate materials or smaller screws may require lower RPMs for precision and to prevent damage.

Maximum Torque

Torque refers to the rotational force generated by the power screwdriver or impact driver. It determines the tool’s ability to drive screws or fasteners into different materials. Higher torque is generally favorable, as it allows for easier and more efficient screwing or drilling. However, it’s essential to strike a balance between torque and control, as excessive torque may lead to overdriving or damaging the material.

3. Chuck Size and Type

Chuck Size

The chuck size plays a crucial role in determining the tool’s versatility and compatibility with various bits. The chuck is the component that holds the screwdriver or drill bits. A larger chuck size typically accommodates a wider range of bits, allowing for more flexibility in terms of the tasks you can undertake. Common chuck sizes for power screwdrivers or impact drivers are 1/4 inch and 3/8 inch.

Chuck Type

The chuck type refers to the mechanism used to secure the bits in place. There are two main types to consider: keyless and keyed chucks. Keyless chucks are more convenient, as they can be tightened or loosened manually without the need for additional tools. Keyed chucks, on the other hand, require a separate key to secure the bits in place. Consider your personal preference and convenience when deciding on the chuck type.

4. Ergonomics and Grip

Weight and Balance

The weight and balance of a power screwdriver or impact driver can significantly impact the comfort and maneuverability of the tool. Look for a model that feels well-balanced in your hand and has a weight that you can comfortably handle for extended periods. Ergonomically designed models often have a comfortable grip and distribute the weight evenly, reducing strain and fatigue during prolonged use.

Handle Design

The handle design of a power screwdriver or impact driver can enhance or hinder your overall experience while using the tool. Look for a handle that fits comfortably in your hand and allows for a firm grip. Some models feature contoured handles that conform to the natural shape of your hand, providing optimal control and reducing hand fatigue.

Grip Material

The grip material used in a power screwdriver or impact driver plays a role in comfort and minimizing slippage. Rubberized or textured grips are often preferred, as they provide a secure hold and reduce the likelihood of the tool slipping out of your hand during operation. When selecting a model, consider the grip material and ensure it suits your preferences and provides a non-slip surface.

5. Drive Types

Hex Drive

Hex drive power screwdrivers or impact drivers are compatible with hexagonal bits. Hex drives are commonly used for tasks that involve heavy-duty fastening or drilling, such as construction or woodworking projects. The hexagonal shape of the drive allows for increased torque transfer, providing more power and stability during operation.

Square Drive

Square drive power screwdrivers or impact drivers feature a square-shaped drive that is compatible with square bits. Square drives are often used for specific applications, such as automotive repairs or machinery maintenance. They offer strong torque transmission and are designed for tasks that require high force and durability.

6. Built-in LED Light

Purpose and Utility

Many power screwdrivers or impact drivers feature a built-in LED light near the chuck. This illumination serves a practical purpose by providing visibility in low-light or confined spaces. The LED light allows you to accurately position the tool and align it with the screws or fasteners, minimizing errors and improving overall precision. When working in dimly lit areas or during nighttime tasks, the built-in LED light can be extremely beneficial.

7. Size and Weight

Portability

The size and weight of a power screwdriver or impact driver directly affect its portability. If you require a tool that you can easily carry around or transport to different work sites, opt for a compact and lightweight model. Compact tools are particularly useful when working in tight or confined spaces that may limit the maneuverability of larger tools.

Working in Tight Spaces

When working in tight or hard-to-reach spaces, the size and weight of the power screwdriver or impact driver become critical. Bulky or heavy tools may impede your ability to access certain areas, hindering your progress and impacting overall efficiency. Choosing a compact and lightweight tool allows for better maneuverability and enables you to work comfortably in confined spaces.

8. Accessories and Bit Compatibility

Included Accessories

When purchasing a power screwdriver or impact driver, it’s worth considering the included accessories that come with the tool. These accessories can vary from manufacturer to manufacturer but may include additional bits, a carrying case, or a charger for cordless models. Assess your specific needs and compare the accessories offered with different models to ensure they align with your requirements.

Bit Compatibility

Compatibility with a wide range of bits is crucial when selecting a power screwdriver or impact driver. Different tasks and materials may require specific types of bits. Check the compatibility of the tool with various bit sizes and types to ensure it can accommodate your needs. Some models offer a quick-change chuck system, allowing for easy and rapid bit swapping, while others may require additional tools for bit changes.

9. Noise and Vibration Levels

Noise Level

Power screwdrivers or impact drivers can generate significant noise during operation. However, some models are designed to minimize noise levels, making them more suitable for use in noise-sensitive environments or for reduced disturbance during home projects. Consider models that advertise reduced noise levels if noise is a concern for you or your surroundings.

Vibration Level

The vibration caused by power screwdrivers or impact drivers can lead to increased hand fatigue and discomfort during extended use. Look for models that feature built-in vibration dampening technology to minimize vibrations transmitted to your hand. Reduced vibration levels enhance comfort and allow for better control and accuracy during operation.

10. Warranty and Customer Support

Manufacturer’s Warranty

When investing in a power screwdriver or impact driver, it’s important to consider the warranty offered by the manufacturer. A warranty provides assurance and protection against potential defects or malfunctions. Look for models with a reputable manufacturer’s warranty that covers a reasonable duration, ensuring you are protected in case of any unforeseen circumstances.

Customer Support

Good customer support is invaluable, especially when dealing with any technical issues or inquiries about the power screwdriver or impact driver. Research the reputation of the manufacturer and their customer support services. Opting for a manufacturer known for responsive and helpful customer support can provide peace of mind and assistance when needed.

In conclusion, when selecting a power screwdriver or impact driver, consider the power source, speed and torque capabilities, chuck size and type, ergonomics and grip comfort, drive types, built-in LED lights, size and weight for portability, included accessories and bit compatibility, noise and vibration levels, as well as the warranty and customer support provided. By considering these various features, you can make an informed decision and choose a power screwdriver or impact driver that best suits your specific needs and preferences.