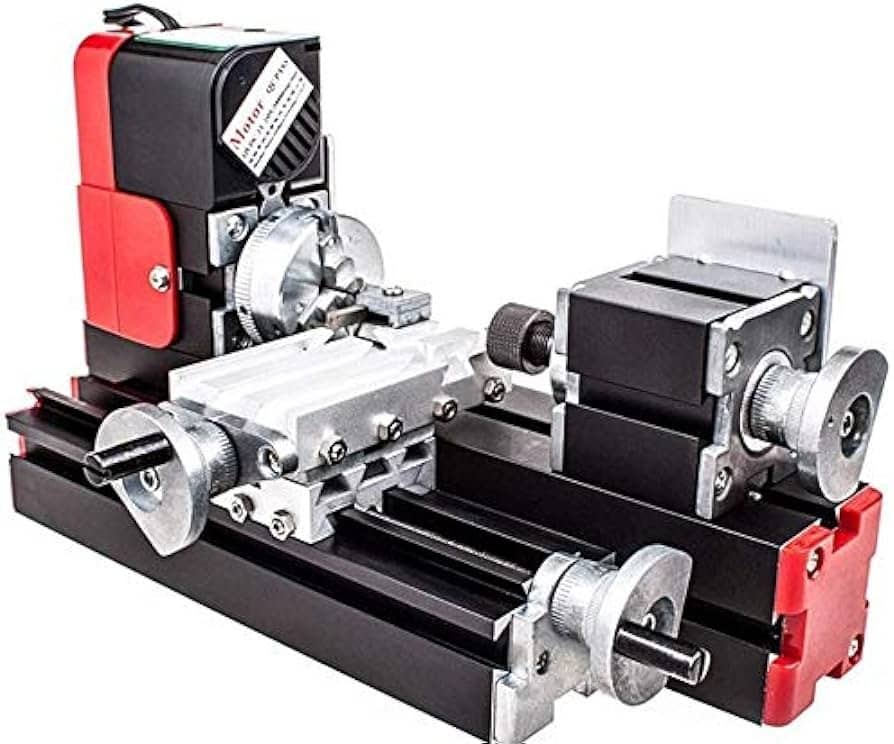

Do you ever find yourself needing a versatile tool that can handle a wide range of tasks? Well, look no further than the multifunction lathe. With its ability to perform various functions such as turning, drilling, milling, and more, this tool offers immense flexibility and convenience. Whether you’re a seasoned professional or a hobbyist, a multifunction lathe can be a game-changer. Not only does it save space in your workshop by combining multiple functions into one machine, but it also allows you to work efficiently and accurately. So, if you’re wondering if a multifunction lathe is a good option, the answer is a resounding yes! Let’s explore further and discover why this tool is a worthwhile investment.

Benefits of a Multifunction Lathe

Increased Versatility

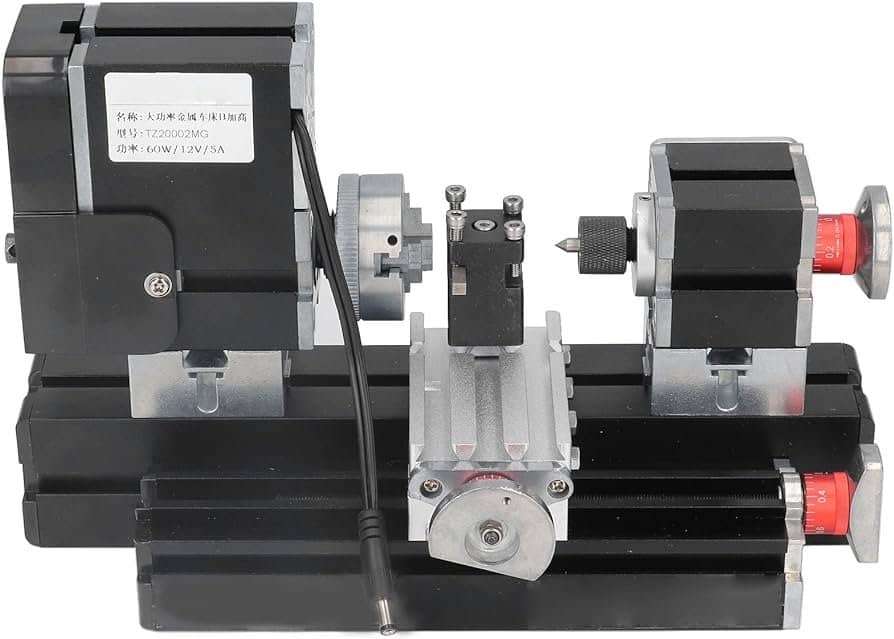

A multifunction lathe provides increased versatility in your workshop or manufacturing facility. With its ability to perform multiple machining processes, such as turning, milling, and drilling, you can complete a wide range of tasks with just one machine. This eliminates the need for separate equipment for each process, saving you both space and money.

Space and Cost Savings

By replacing multiple single-function machines with a multifunction lathe, you can free up valuable floor space in your workshop. This is especially beneficial if you have limited space or are looking to optimize your current layout. Additionally, investing in a multifunction lathe can save you money in the long run. Instead of purchasing individual machines for each specific task, you only need to invest in one multifunction lathe, reducing both upfront and maintenance costs.

Time Savings

One of the significant advantages of using a multifunction lathe is the time savings it offers. With a single machine capable of performing various operations, you can streamline your workflow and complete projects more efficiently. Instead of transferring workpieces between different machines, you can seamlessly transition from one process to another, minimizing downtime and maximizing productivity.

Common Multifunction Lathe Features

Adjustable Speeds

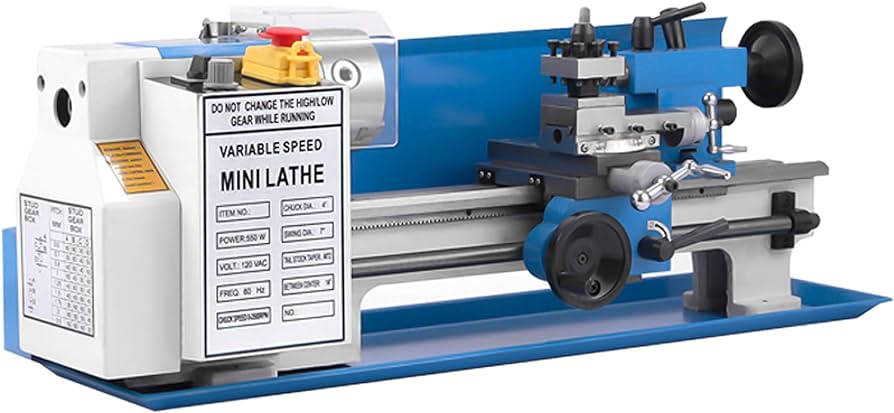

Most multifunction lathes come with adjustable speeds, allowing you to tailor the machine’s performance to suit different materials and machining requirements. This flexibility enables you to achieve optimal results and maintain precision, regardless of the specific task at hand.

Multiple Cutting Tools

Another key feature of multifunction lathes is their ability to accommodate multiple cutting tools. From turning tools to milling cutters and drilling bits, these machines can effortlessly switch between different tools, eliminating the need for tool changes or manual adjustments. This versatility enhances efficiency and saves valuable setup time.

Digital Controls

Many multifunction lathes are equipped with digital controls, which offer precise control over various machining parameters. These controls allow you to set and adjust spindle speed, feed rate, and other essential variables with ease. The digital interface provides accurate readings and ensures consistency in your machining processes, resulting in high-quality workpieces.

Applications of a Multifunction Lathe

Turning

The primary function of a lathe, regardless of its multifunction capabilities, is turning. Turning involves rotating a workpiece against a cutting tool to shape it symmetrically. With a multifunction lathe, you can easily turn cylindrical objects, create taper cuts, and generate threads, making it suitable for a wide range of applications, including creating precision parts, woodworking, and metalworking.

Milling

Milling involves removing material from a workpiece using rotating cutting tools. With the milling capabilities of a multifunction lathe, you can perform tasks such as face milling, slotting, and contouring. This is particularly useful for creating complex shapes, producing precision components, and working with materials like metal, wood, and plastic.

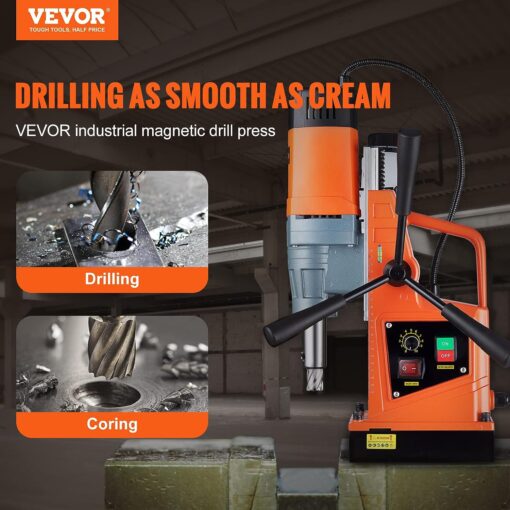

Drilling

Drilling is the process of creating holes in a workpiece using a rotating drill bit. A multifunction lathe with drilling capabilities allows you to accurately create holes of various sizes and depths. Whether you are working with metal, wood, or other materials, the drilling function of a multifunction lathe can greatly simplify the process and ensure precise results.

Factors to Consider Before Choosing a Multifunction Lathe

Workpiece Size and Weight

When selecting a multifunction lathe, it is crucial to consider the size and weight of the workpieces you typically handle. Ensure that the lathe’s specifications, such as swing over bed and maximum weight capacity, align with your requirements. Oversized or overweight workpieces may strain the machine and affect its performance, leading to inaccurate results or potential damage.

Required Precision

Different machining tasks may have varying precision requirements. Consider the level of precision needed for your workpieces and ensure that the multifunction lathe you choose can deliver the necessary accuracy. Look for features such as precision gearboxes, rigid construction, and advanced control systems that contribute to maintaining tight tolerances.

Budget

Like any other investment, it is essential to establish a budget when considering a multifunction lathe. Determine how much you are willing to spend and consider the long-term return on investment. While multifunction lathes may have a higher upfront cost compared to single-function machines, the elimination of additional equipment expenses and potential productivity gains can make them a cost-effective choice in the long run.

Maintenance and Durability Considerations

Lubrication and Cleaning

Proper lubrication and regular cleaning are crucial for the smooth operation and longevity of a multifunction lathe. Follow the manufacturer’s guidelines for lubricating the machine’s moving parts, such as the spindle, gears, and slides. Additionally, remove chips, dust, and other debris from the lathe regularly to prevent interference with its performance.

Regular Maintenance Schedule

Establish a regular maintenance schedule for your multifunction lathe to ensure ongoing performance and prevent unnecessary breakdowns. Schedule routine inspections, servicing, and parts replacements as recommended by the manufacturer. Regular maintenance will help identify any potential issues early on and keep your lathe in optimal working condition.

Build Quality

Consider the build quality of the multifunction lathe before making a purchase. Look for machines constructed with durable materials, such as cast iron or high-quality steel. These robust materials can withstand heavy use and provide the necessary stability and rigidity for accurate machining. Investing in a lathe with excellent build quality ensures its durability and longevity.

Potential Limitations of a Multifunction Lathe

Limited Specialization

While multifunction lathes offer versatility, they may not excel in specialized tasks compared to dedicated machines. If your work requires highly specialized processes, such as thread milling or gear cutting, a single-function machine specifically designed for that task may yield better results. Assess the specific requirements of your projects and determine if a multifunction lathe can adequately meet your needs.

Learning Curve for New Operators

Operating a multifunction lathe may involve a learning curve, especially for operators accustomed to single-function machines. Familiarizing oneself with the various features, controls, and application techniques may take time. Ensure that your operators receive proper training and have access to resources, such as user manuals and tutorials, to maximize their efficiency and minimize errors.

Higher Initial Investment

Compared to single-function machines, multifunction lathes generally have a higher initial cost. This can be a significant investment, particularly for small businesses or individuals with budget constraints. However, when evaluating the long-term benefits and potential cost savings associated with a multifunction lathe, the initial investment may be justified by improved efficiency, space optimization, and increased capabilities.

Choosing the Right Multifunction Lathe for Your Needs

Assessing Workpiece Requirements

Before selecting a multifunction lathe, thoroughly assess your workpiece requirements. Consider factors such as size, weight, and specific machining operations needed. Ensure that the lathe you choose can accommodate your workpieces and perform the required tasks with the desired precision.

Evaluating Available Features

Carefully evaluate the features offered by different multifunction lathes. Consider the range of speeds, cutting tools, control systems, and other specifications available. Determine which features are essential for your applications and select a lathe that provides the necessary capabilities to meet your machining needs effectively.

Quality and Warranty

Ensure that the multifunction lathe you choose is of high quality and backed by a reliable warranty. Look for reputable manufacturers known for producing durable and reliable machines. A solid warranty not only provides peace of mind but also ensures that you have access to support and service in case of any issues with the machine.

Training and Support

Operator Training

To optimize the use of your multifunction lathe, provide thorough training to your operators. Familiarize them with the machine’s features, controls, and safe operating procedures. Training programs can improve efficiency, reduce errors, and enhance overall productivity. Work with the manufacturer or training providers to develop a comprehensive training program tailored to your specific machine and applications.

Technical Support

Choose a manufacturer or supplier that offers reliable technical support for their multifunction lathes. Technical assistance can be invaluable when troubleshooting issues, understanding complex features, or optimizing your machine’s performance. Ensure that the vendor provides timely and knowledgeable support to address any concerns or questions you may have.

Availability of Spare Parts

Investigate the availability of spare parts for the multifunction lathe you are considering. Over time, your lathe may require replacement parts or repairs. Manufacturers who offer readily available spare parts and a well-established supply chain can minimize downtime and ensure uninterrupted operation of your machine.

Safety Precautions and Regulations

Protective Gear

Prioritize safety when operating a multifunction lathe by providing appropriate protective gear to operators. Safety glasses, gloves, and ear protection should be worn to prevent injuries from flying debris, sharp tools, and excessive noise. Ensure that operators are aware of the safety gear requirements and adhere to them at all times.

Safe Operating Procedures

Follow safe operating procedures to minimize the risk of accidents and injuries. Familiarize operators with the lathe’s safety features and emergency stop mechanisms. Clear work areas of potential hazards, such as loose materials or trailing cables. Regularly inspect the machine for any signs of wear or damage that may compromise safety.

Compliance with Safety Standards

Ensure that your multifunction lathe meets the necessary safety standards and regulations. Compliance with safety standards, such as those set by organizations like Occupational Safety and Health Administration (OSHA) or the European Union’s Machinery Directive, helps protect operators and ensures you are meeting legal requirements in your jurisdiction.

Real-Life User Experiences

Positive Testimonials

Many users of multifunction lathes have reported positive experiences and benefits. They praise the versatility and time savings offered by these machines, allowing them to complete a range of tasks efficiently. Users appreciate the space and cost savings achieved by consolidating multiple machines into one and highlight the quality and precision achieved with multifunction lathes.

Negative Feedback

Some users have reported challenges with the learning curve associated with operating multifunction lathes. They have noted that it takes time for operators to become proficient with the various functions and controls. Additionally, a few users have experienced issues with reliability and breakdowns, emphasizing the importance of choosing a quality machine from a reputable manufacturer.

Performance in Different Industries

Multifunction lathes have found applications in various industries, including automotive, aerospace, general manufacturing, and woodworking, among others. Users in these industries have reported improved productivity, enhanced precision, and greater flexibility in their machining operations. The versatility of these machines has allowed them to tackle a wide range of projects effectively.

In conclusion, a multifunction lathe can be a valuable addition to your workshop or manufacturing facility, offering increased versatility, space and cost savings, and time efficiency. By carefully considering factors such as workpiece requirements, available features, quality, and ongoing support, you can choose the right multifunction lathe that meets your specific needs. With proper maintenance, training, and adherence to safety precautions, a multifunction lathe can empower you to achieve high-quality results in a wide range of machining applications.