Power tools can be incredibly useful when it comes to taking on DIY projects or completing repairs around the house. However, it’s important to prioritize your safety when using these powerful machines. In this article, you will discover the essential tips and precautions to ensure that you can confidently and securely use power tools, minimizing the risk of accidents or injuries. So, whether you’re a seasoned DIY enthusiast or new to power tools, read on to learn how to harness their potential safely and effectively.

Selecting the Right Power Tools

When it comes to selecting the right power tools, it’s important to do your research and consider a few factors before making a decision. With so many different types of power tools available on the market, it can be overwhelming to know which one will suit your needs best. By understanding the different types of power tools and determining your specific needs, you can make an informed choice that will help you accomplish your tasks efficiently and safely.

Researching the Different Types of Power Tools

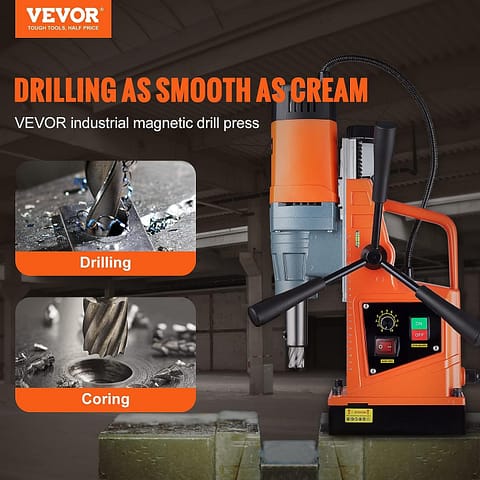

Before diving into the world of power tools, it’s essential to have a basic understanding of the different types available. From drills and saws to sanders and routers, each power tool serves its unique purpose. Take the time to research and learn about their features, functions, and applications. By doing so, you can narrow down your options and choose the power tools that align with the tasks you frequently perform.

Determining the Specific Power Tool You Need

Once you’ve familiarized yourself with the various types of power tools, it’s time to determine the specific power tool you need for your projects. Consider the tasks you commonly undertake and identify the tool that will help you accomplish them with ease. For example, if you frequently work with wood, a circular saw or a router might be essential for your toolkit. By accurately assessing your needs, you can invest in the right power tool and ensure its effectiveness.

Considering the Power Source: Corded or Cordless

Another crucial factor to consider when selecting power tools is the power source. Power tools come in two main types: corded and cordless. Corded power tools require an electrical outlet for operation, whereas cordless power tools are battery-powered and offer portability and flexibility. Consider your workspace and the requirements of your projects to determine which power source will be the most convenient for you. Keep in mind that cordless power tools may require battery replacements or recharging, so factor in the cost and availability of batteries.

Choosing the Right Brand and Model

After narrowing down your options, it’s time to choose the right brand and model for your power tools. Brand reputation and reliability are essential considerations, as you want to invest in tools that will last and perform well. Look for reputable manufacturers known for their quality and durability. Additionally, consider reading reviews and seeking recommendations from professionals or experienced DIY enthusiasts. By choosing the right brand and model, you can have confidence in the performance and longevity of your power tools.

Reading the Instruction Manual

Once you have selected and acquired your power tools, it’s crucial to read and understand the instruction manual before using them. The instruction manual provides valuable information on safety guidelines, features, functions, and proper operating procedures. By taking the time to familiarize yourself with the manual, you can ensure your safety and make the most out of your power tools.

Understanding the Safety Guidelines

Before operating any power tool, it’s essential to have a clear understanding of the safety guidelines outlined in the instruction manual. Safety should always be a top priority when using power tools to avoid accidents and injuries. The manual will provide specific safety precautions, such as wearing appropriate personal protective equipment (PPE), maintaining a safe workspace, and handling the tool correctly. Make sure to carefully read and follow these guidelines to minimize the risk of accidents.

Familiarizing Yourself with the Tool’s Features and Functions

Each power tool has unique features and functions that enhance its capabilities. By reading the instruction manual, you can familiarize yourself with these features and understand how to utilize them effectively. For example, some power tools may have adjustable speed settings or different blade attachments. Understanding these features will allow you to optimize your tool’s performance and achieve accurate results.

Learning the Proper Operating Procedures

To ensure both your safety and the longevity of your power tools, it’s crucial to learn and follow the proper operating procedures recommended by the manufacturer. The instruction manual will provide step-by-step instructions on how to handle and operate the tool correctly. This includes details on starting and stopping the tool, adjusting settings, and performing maintenance tasks. By adhering to these procedures, you can use your power tools safely and prolong their lifespan.

Inspecting the Power Tool

Before using any power tool, it’s essential to inspect it thoroughly to ensure it is in proper working condition. Regular inspections help identify any damaged or worn-out parts that may compromise the tool’s performance or pose safety risks. By conducting a visual inspection and systematic check, you can have peace of mind knowing that your power tool is safe and ready for operation.

Checking for Damaged or Worn Out Parts

Inspecting your power tool for damaged or worn-out parts is crucial to prevent accidents and ensure optimal performance. Look for any cracked or frayed cords, broken switches, or loose connections. Additionally, check the blades, bits, or attachments for any signs of wear or damage. If you notice any issues, it’s important to address them promptly by replacing the damaged parts or seeking professional assistance.

Ensuring Proper Safety Features are Intact

Most power tools are equipped with safety features designed to minimize the risk of accidents. During your inspection, verify that these safety features are intact and functioning correctly. This may include safety guards, blade brakes, or automatic shut-off features. Ensuring that these safety mechanisms are in place will provide an additional layer of protection during your work.

Verifying the Power Tool’s Stability

Stability is key when working with power tools. Before starting your project, verify that your power tool is stable and secure. Check the base or platform on which the tool sits and ensure it is level. If using a handheld power tool, ensure that the grip is tight and comfortable. By verifying the stability of your power tool, you can work with confidence and prevent accidents caused by unstable equipment.

Personal Protective Equipment (PPE)

When working with power tools, it’s crucial to prioritize your safety by wearing appropriate personal protective equipment (PPE). PPE acts as a barrier between you and potential hazards, reducing the risk of injuries. It’s important to identify the specific PPE required for the tool you are using and ensure you wear it consistently throughout your projects.

Wearing Eye Protection

Power tools can generate flying debris, dust, or sparks that can pose a significant risk to your eyes. To protect yourself, always wear appropriate eye protection, such as safety glasses or goggles. Ensure that your eye protection is ANSI-approved and provides adequate coverage for your eyes. This will prevent any potential eye injuries and safeguard your vision.

Using Hearing Protection

Many power tools produce loud noises that can damage your hearing if you are exposed to them for an extended period. To safeguard your hearing, it’s crucial to use hearing protection, such as earplugs or earmuffs, when operating noisy power tools. Ensure that your hearing protection has a suitable noise reduction rating (NRR) to provide adequate hearing conservation.

Using Respiratory Protection

Certain power tools, such as sanders or grinders, can generate dust or fine particles that pose a respiratory hazard. To protect your lungs from potential harm, use respiratory protection, such as a suitable dust mask or respirator. Choose a mask or respirator that is appropriate for the level of dust or particles generated by your power tool and ensure a proper fit for optimal protection.

Wearing Protective Gloves

Protective gloves are essential when handling power tools to prevent injuries to your hands and fingers. Choose gloves that are appropriate for the specific task and provide ample dexterity and grip. For example, when working with sharp blades or rough surfaces, wear cut-resistant or impact-resistant gloves. Always ensure a snug fit to maintain control and avoid any interference with the operation of the power tool.

Choosing Appropriate Clothing and Footwear

When working with power tools, it’s important to wear suitable clothing and footwear that will protect you from potential hazards. Avoid loose clothing or jewelry that can get caught in moving parts. Opt for snug-fitting apparel that allows freedom of movement and does not restrict your ability to operate the power tool safely. Additionally, wear closed-toe shoes with slip-resistant soles to provide adequate foot protection and prevent trips or falls.

Setting Up a Safe Workspace

Creating a safe workspace is crucial when working with power tools. By setting up your workspace properly, you can significantly reduce the risk of accidents and ensure a smooth and efficient workflow.

Working in a Well-lit Area

Good lighting is essential when working with power tools as it allows you to see your work clearly and identify potential hazards. Ensure that your workspace is well-lit, either by natural light or appropriate artificial lighting. Place portable work lights strategically to eliminate shadows and improve visibility in dimly lit areas.

Ensuring Sufficient Ventilation

Certain power tools generate fumes or dust that can be hazardous if inhaled. To protect your health, it’s important to ensure sufficient ventilation in your workspace. If working indoors, open windows or use fans to improve air circulation. If working in a confined space, consider using exhaust fans or wearing respiratory protection, as appropriate, to minimize the inhalation of harmful substances.

Clearing the Workspace of Clutter

A cluttered workspace increases the risk of accidents and makes it more challenging to navigate safely. Before starting your project, clear your workspace of any unnecessary items or debris. Make sure to organize your tools and materials in a designated area to maintain an organized and hazard-free workspace.

Securing the Workpiece Properly

When working with power tools, securing the workpiece properly is essential to prevent it from moving or shifting unexpectedly. Use clamps, vises, or other suitable fixtures to hold the workpiece securely. This will allow you to work with precision and reduce the likelihood of accidents caused by the workpiece moving unintentionally.

Avoiding Tripping Hazards

Trips and falls are common causes of injuries when working with power tools. To prevent such accidents, ensure that your workspace is free from potential tripping hazards. Keep cords and cables neatly arranged and secured to prevent them from becoming tangled or creating obstacles. Make sure your workspace floor is clear of clutter, spills, or loose objects that could cause you to lose your balance.

Power Tool Precautions

Taking specific precautions with your power tools is essential for your safety and the longevity of the equipment. By following these precautions, you can reduce the risk of accidents and ensure the optimal performance of your power tools.

Inspecting and Checking Power Cords

Power cords are crucial components of corded power tools. Before using a corded power tool, inspect the power cord for any signs of damage, such as cuts, fraying, or exposed wires. If you notice any issues, replace or repair the power cord before operating the tool. Additionally, make sure the power cord is free from knots or tangles that could restrict movement or create tripping hazards.

Keeping the Work Area Dry

Water and electrical power tools do not mix well. To prevent electric shock hazards, ensure that your work area is dry before operating any power tool. If you need to work in a damp or wet environment, use appropriate electrical safety precautions, such as using a ground fault circuit interrupter (GFCI) or waterproof power tools. Never use power tools with wet hands.

Avoiding Electric Shock Hazards

Electric shock hazards can be present when working with power tools. To minimize this risk, ensure that you are using properly grounded outlets or using appropriate electrical extension cords. Avoid contact between power tools and water, as this can lead to electrical shock. If you notice any abnormalities or malfunctions with your power tools, such as electric shocks or unusual sounds, stop using them immediately and seek professional assistance.

Using Ground Fault Circuit Interrupters (GFCI)

Ground Fault Circuit Interrupters (GFCIs) are essential safety devices that protect against electric shock hazards. When working in areas where the risk of water contact is high, such as kitchens or bathrooms, it’s important to use GFCIs. This electrical device detects any imbalances in electrical currents and quickly shuts off power to prevent electrical shocks. Use GFCI-protected outlets or portable GFCIs when operating power tools in potentially wet or damp locations.

Proper Handling and Transport

Proper handling and transport of power tools are essential for their safe operation and longevity. Always handle your power tools with care, avoiding any rough or excessive force. Never carry a power tool by its cord and refrain from yanking on cords to unplug them. When transporting power tools, ensure that they are switched off, unplugged, and securely stored to prevent accidental activation or damage.

Handling Power Tools

Knowing how to handle power tools properly is crucial for your safety and the effectiveness of your work. By following these guidelines, you can minimize the risk of accidents and achieve accurate results.

Maintaining a Firm Grip

When using power tools, it’s essential to maintain a firm grip to control the tool and reduce the risk of it slipping from your hand. Ensure that you have a comfortable grip on the tool’s handle, using both hands whenever possible. Keep your grip steady but avoid excessive force that could lead to fatigue or loss of control.

Avoiding Loose Clothing and Jewelry

Loose clothing or jewelry can get caught in moving parts of power tools, posing a significant risk of injury. Before operating a power tool, ensure that you are not wearing any loose or dangling clothing and remove any jewelry that could prove hazardous. Opt for clothing that fits well and allows for ease of movement.

Keeping Hands Clear of Moving Parts

It is essential to keep your hands clear of the moving parts of power tools at all times. Avoid placing your hands near the blades, bits, or any other parts that rotate or have a cutting action. When operating a power tool, maintain a safe distance between your hands and the moving parts to prevent accidental contact and potential injuries.

Using Tools at Appropriate Speeds and Settings

Power tools often come with adjustable speeds or different settings to accommodate various materials or tasks. It’s crucial to use the appropriate speed and setting for your specific project. Using the wrong speed or setting can lead to inefficient work and potentially cause damage to the material or the power tool itself. Consult the instruction manual or seek guidance from experienced users to determine the best speed and setting for your application.

Using the Power Tool Safely

When operating power tools, it’s important to prioritize your safety by following proper techniques and positioning. By adopting safe practices, you can minimize the risk of accidents and ensure the best possible results.

Keeping a Balanced Stance

Maintaining a balanced stance is essential when using power tools. Position your feet comfortably shoulder-width apart, distributing your weight evenly. This stable stance will provide you with better balance and control over the power tool during operation. Avoid standing on unstable surfaces or using power tools when in an awkward or unbalanced position.

Positioning Yourself Correctly

Positioning yourself correctly in relation to the power tool is crucial for your safety. Stand in a way that allows you to have a clear view and control of the tool’s movements. Never reach over a running tool or operate it from a position that compromises your stability or line of sight. Move your body and adjust your position, if necessary, to ensure you can safely use the power tool.

Directing the Tool Away from Your Body

When using power tools, always direct the tool away from your body and any bystanders. This prevents potential injuries in case of kickbacks, blade or bit breakages, or flying debris. Be aware of the tool’s rotation or cutting direction and ensure that you are positioned accordingly. If working with others, make sure they are at a safe distance from the tool and any potential line of fire.

Using Two Hands Whenever Possible

Power tools are designed to be operated with both hands for better control and reduced strain on your body. Whenever possible, use both hands to grip and control the tool correctly. This applies to tools such as drills, saws, or sanders. By using both hands, you can maintain stability and minimize the risk of accidents caused by losing control of the tool.

Proper Cutting Techniques

When using power tools for cutting tasks, utilizing proper techniques will ensure accurate results and prevent accidents. By following these cutting techniques, you can achieve precise cuts while keeping yourself safe.

Marking Your Cuts

Before making any cuts, it’s important to mark the area accurately. Use a pencil or appropriate marking tool to outline the cutting path or indicate the desired depth. This will help you maintain control and make precise cuts without unnecessary guesswork.

Using Guides and Jigs

To ensure accurate and consistent cuts, consider using guides or jigs that are designed for your specific power tool. These accessories can assist in keeping the tool aligned and provide a controlled cutting path. Guides and jigs can be particularly useful for tasks that require repetitive cuts or cutting along a specific angle.

Applying Steady and Controlled Pressure

When applying pressure to the power tool during cutting, it’s important to maintain a steady and controlled force. Avoid exerting excessive pressure, as this can lead to a loss of control or cause the tool to kick back unexpectedly. Apply a consistent pressure that allows the tool to cut smoothly and efficiently.

Avoiding Forceful or Jerky Movements

Forceful or jerky movements during cutting can result in uneven cuts or dangerous accidents. To achieve clean and precise cuts, it’s important to maintain a steady and smooth motion. Push or guide the tool with steady pressure, allowing the tool’s blades or bits to do the work. Avoid pushing or pulling the tool forcefully, as it may lead to blade or bit breakages or cause the tool to jump.

Maintaining and Storing Power Tools

Proper maintenance and storage of your power tools are essential to ensure their performance, longevity, and safety. By following these practices, you can keep your power tools in optimal condition and ready for use.

Cleaning the Power Tools Regularly

Regular cleaning helps remove dust, debris, and residue that can accumulate on power tools over time. Clean the exterior, handles, and blades or bits of your power tools after each use. Use a soft brush or cloth to remove dust or debris, and consider using appropriate cleaning solutions if necessary. Regularly cleaning your power tools will not only keep them looking good but also prevent any buildup that could affect their performance.

Checking and Replacing Blades, Bits, and Attachments

The blades, bits, and attachments of power tools are subject to wear and tear with use. Regularly inspect these components for signs of damage or bluntness and replace them as needed. Dull or damaged blades or bits can compromise the effectiveness and safety of your power tool. Stay aware of the manufacturer’s recommendations regarding the lifespan of these components and follow their guidelines for replacement intervals.

Storing Power Tools in a Safe and Dry Area

Proper storage is crucial to protect your power tools from damage and maintain their functionality. After use, store your power tools in a clean, dry area that offers protection from dust, moisture, and extreme temperatures. Use appropriate cases, bags, or boxes to store and transport your power tools, ensuring they are properly secured. Storing your power tools correctly will prolong their lifespan and preserve their performance.

Properly Coiling and Storing Power Cords

Power cords, when left uncoiled or tangled, can pose tripping hazards and become damaged. After each use, properly coil the power cord according to the manufacturer’s recommendations. Avoid excessive bending or twisting that could damage the cord’s insulation or conductors. Storing power cords separately from the power tools and securing them with cord wraps or clips will help keep them organized and prevent unnecessary wear or damage.

By following these comprehensive guidelines, you can ensure the safe and effective use of power tools in various applications. Remember, safety should always be a top priority, and taking the time to select the right tools, understand their features, and use them correctly will result in successful projects and a safer working environment.