If you have ever wondered whether or not investing in a metal lathe is a worthwhile decision, look no further. This article aims to shed light on the benefits and practicality of owning a metal lathe. Whether you are a seasoned handyman or a DIY enthusiast, understanding the uses and advantages of this versatile tool will help you make an informed decision. From crafting intricate metal designs to repairing essential components, a metal lathe opens up a world of possibilities. So, before you dismiss the idea, let’s explore why a metal lathe may just become your new favorite tool.

What is a Metal Lathe?

A metal lathe is a versatile machine used in metalworking, specifically for shaping and machining metal materials. It is a tool that holds and rotates a workpiece while various cutting tools are applied to shape it. Metal lathes are commonly used in industries such as manufacturing, automotive, and aerospace.

Definition

A metal lathe, also known as an engine lathe or a center lathe, is a machine that rotates a workpiece on its axis and uses various cutting tools to remove material and shape the piece. The lathe is equipped with a spindle, chuck, and tailstock, allowing for precise cutting and shaping operations.

Functionality

The functionality of a metal lathe lies in its ability to rotate a workpiece and move cutting tools along its surface, allowing for the creation of various shapes and designs. It can perform operations such as turning, facing, drilling, taper turning, and knurling. The operator can accurately control the speed and depth of the cuts to ensure precision in the final product.

Benefits of Owning a Metal Lathe

Owning a metal lathe brings several benefits, making it a valuable asset for any metalworking enthusiast or professional.

Versatility

One of the key advantages of owning a metal lathe is its versatility. With this machine, you can perform a wide range of operations on different types of metal materials. Whether you need to turn a cylindrical shape, face a flat surface, or create intricate designs, a metal lathe can handle it. Its adaptability makes it a valuable tool for a variety of projects.

Precision

Precision is crucial in metalworking, and a metal lathe excels in this aspect. The machine allows for precise control over cutting depths and speeds, enabling you to achieve accurate dimensions and desired finishes. Whether you are working on a small intricate part or a larger workpiece, a metal lathe can help you achieve the precision required for a high-quality end result.

Cost-effectiveness

Investing in a metal lathe can lead to cost savings in the long run. By owning your own machine, you eliminate the need to outsource machining tasks or rely on expensive metalworking services. With a metal lathe at your disposal, you have greater flexibility and independence in your metalworking projects, ultimately saving you money over time.

Considerations Before Purchasing a Metal Lathe

Before purchasing a metal lathe, there are several important factors to consider to ensure that you choose the right machine for your needs.

Available Space

Metal lathes come in various sizes, and it is vital to consider the space you have available in your workshop or garage. Measure the dimensions of the lathe and ensure that you have sufficient space for the machine, as well as for movement around it. Factor in both the lathe’s footprint and its clearance requirements.

Budget

As with any machinery purchase, it is crucial to establish a budget for your metal lathe. Consider your needs and future projects when determining how much you can spend. Keep in mind that higher-quality, more versatile machines may have a higher price tag, but they might offer better long-term value and durability.

Frequency of Use

Evaluate how frequently you plan to use the metal lathe. If you are a professional or a frequent user, investing in a more high-end and feature-rich machine might be worthwhile. However, if you only intend to use the lathe occasionally or for hobby projects, a more basic model might meet your requirements without breaking the bank.

Types of Metal Lathes

Metal lathes come in different types, each designed for specific purposes and applications. Familiarize yourself with the various types to choose the one that best suits your needs.

Benchtop Metal Lathes

Benchtop metal lathes are compact and portable, making them ideal for small workshops or hobbyists with limited space. They are versatile and capable of handling smaller projects. Benchtop lathes often have limited horsepower and size capacities, but they offer convenience and ease of use for smaller-scale tasks.

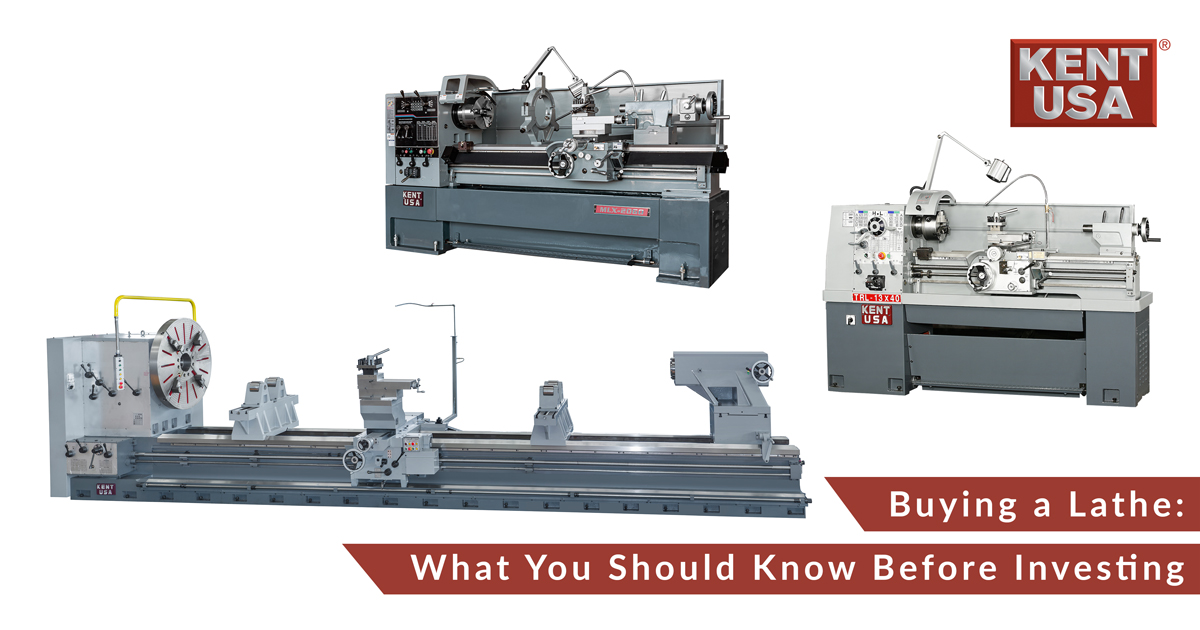

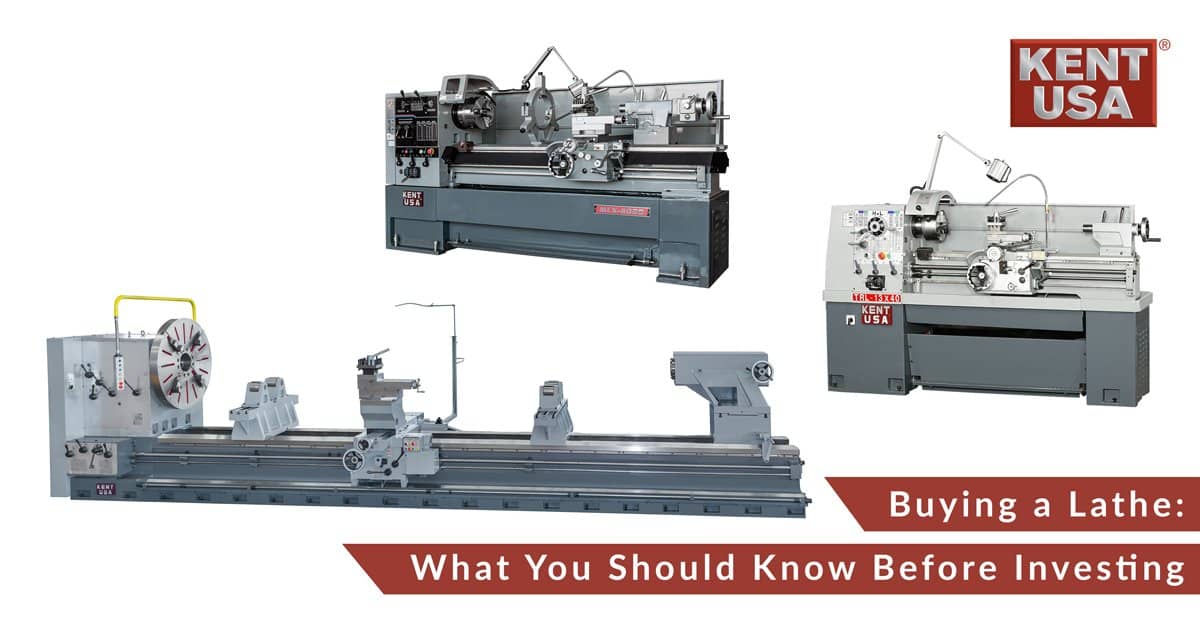

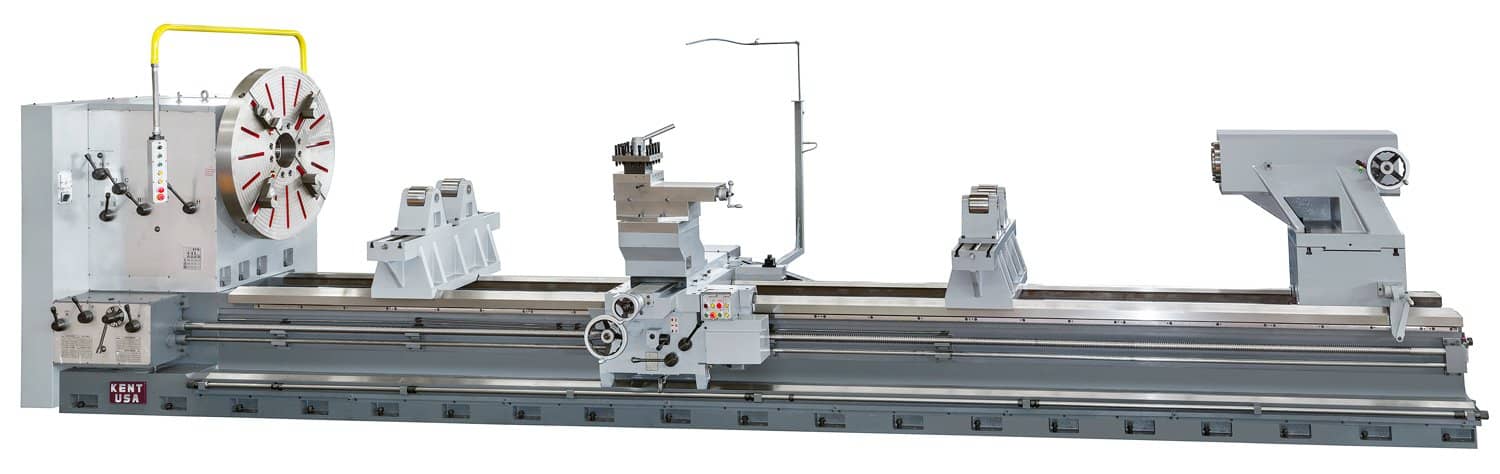

Engine Metal Lathes

Engine lathes, also known as center lathes, are larger and more robust machines designed for heavy-duty machining operations. These lathes have higher horsepower and size capacities, making them suitable for industrial applications. Engine lathes are capable of handling larger workpieces and can perform a wide array of operations with precision.

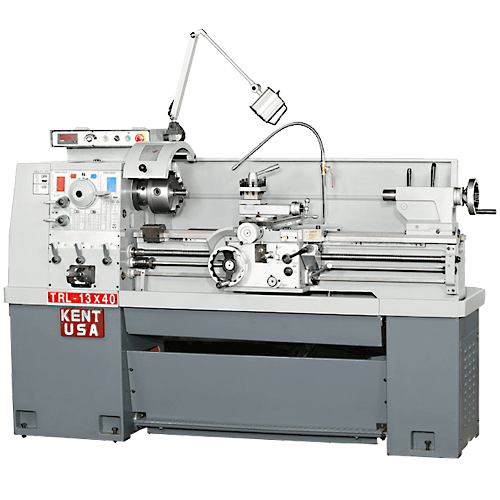

Toolroom Metal Lathes

Toolroom lathes are known for their precision and versatility. They are commonly found in toolrooms and are used for manufacturing tools, parts, and prototypes. Toolroom lathes may offer advanced features such as digital readouts, power feeds, and quick-change tooling systems. These lathes are often a top choice for professionals seeking precision and flexibility.

Projects You Can Accomplish with a Metal Lathe

A metal lathe opens up a world of possibilities for creating various projects. Here are some of the common operations you can accomplish with a metal lathe.

Turning

Turning is the most fundamental operation performed on a metal lathe. It involves rotating a workpiece against a cutting tool to remove material and create cylindrical shapes. Whether you need to turn dowels, shafts, or bowls, a metal lathe enables you to create accurate and symmetrical cylindrical forms.

Facing

Facing refers to the process of creating a flat surface on the end of a workpiece. This operation is often necessary when joining two pieces together or when creating a finished surface. A metal lathe allows you to face the end of a workpiece with precision and accuracy, ensuring a proper fit and optimal surface finish.

Tapered Turning

Tapered turning involves reducing the diameter of a workpiece gradually along its length to create a tapered shape. This operation is commonly used in applications such as creating conical shapes, machine tool tapers, and aligning parts. With a metal lathe, you can easily achieve precise and consistent tapering in your projects.

Drilling

While a metal lathe primarily focuses on turning operations, it can also be used for drilling holes in workpieces. A lathe’s tailstock can hold a drill chuck, allowing you to perform accurate and centered drilling operations. This versatility saves you from investing in a separate drilling machine, making a metal lathe a cost-effective choice.

Knurling

Knurling is a process used to create a pattern of parallel ridges or serrations on a workpiece’s surface for improved grip or decoration. With a knurling tool attachment, a metal lathe enables you to create precise and consistent knurled surfaces on cylindrical or flat workpieces. This adds both functionality and aesthetic appeal to your projects.

Basic Safety Precautions

When using a metal lathe, it is crucial to prioritize safety to prevent accidents and injury. Here are some basic safety precautions to follow:

Wearing Safety Gear

Always wear appropriate safety gear when operating a metal lathe. This includes safety glasses or goggles to protect your eyes from debris, ear protection to safeguard against noise, and gloves to protect your hands from sharp edges or hot surfaces. Additionally, avoid wearing loose clothing or jewelry that could become entangled in the machine.

Proper Tool Handling

Handle cutting tools with care to avoid accidents. Always ensure that the lathe is turned off and unplugged before changing or adjusting tools. When inserting or removing cutting tools, use a wrench or other appropriate tool to avoid potential injuries from slipping or contact with sharp edges.

Safe Work Environment

Maintain a clean and organized work environment. Clear away any debris or clutter that could pose a tripping hazard. Keep the area well-lit and ensure that your workspace is properly ventilated to prevent the buildup of fumes or harmful particles. Additionally, familiarize yourself with emergency stop procedures and ensure that they are easily accessible.

Maintaining a Metal Lathe

Proper maintenance is crucial to keep your metal lathe in optimal condition and extend its lifespan. Here are some essential maintenance tasks to perform regularly:

Regular Cleaning

Regularly clean your metal lathe to remove excess debris, oil, and dirt that can accumulate during use. Use a brush or compressed air to clean hard-to-reach areas. Avoid using water unless specifically recommended by the lathe’s manufacturer to prevent rusting or damage.

Lubrication

Lubrication is essential to minimize friction and extend the life of your lathe. Regularly lubricate the moving parts of the lathe, such as the spindle, gears, and slideways, with the appropriate lubricating oil or grease recommended by the manufacturer. Be sure to follow the manufacturer’s guidelines to ensure proper lubrication.

Checking and Replacing Parts

Periodically inspect your lathe for worn or damaged parts and replace them as needed. This includes checking belts, gears, chuck jaws, and any other components that may experience wear over time. Regular maintenance and part replacement will help ensure the continued accuracy and performance of your metal lathe.

Learning to Use a Metal Lathe

Learning to use a metal lathe effectively requires proper guidance and practice. Here are some ways to gain the necessary skills:

Seeking Professional Guidance

Consider seeking guidance from professionals or experts in metalworking. Reach out to local trade schools, vocational colleges, or metalworking associations to inquire about courses or training programs that teach lathe operation. Learning from experienced instructors can provide you with valuable knowledge and guidance.

Attending Workshops

Look for workshops or seminars offered by manufacturers, machine tool distributors, or local metalworking groups. These workshops often provide hands-on experience and cover various lathe operations and techniques. Attending such events can help you hone your skills and gain insights from experienced professionals in the industry.

Online Tutorials and Resources

Take advantage of the abundance of online tutorials, videos, and resources available for learning lathe operation. Websites, forums, and video platforms are filled with instructional content that can guide you through different operations and techniques. These resources can be accessed conveniently and often at no cost, allowing you to learn at your own pace.

Alternatives to Owning a Metal Lathe

While owning a metal lathe offers numerous benefits, it may not be necessary for everyone. Consider these alternatives if owning a lathe is not feasible:

Renting or Borrowing

If you have occasional metalworking projects or limited space, consider renting or borrowing a metal lathe. Many tool rental shops or metalworking communities offer this option, allowing you to have access to the machine when needed without the long-term commitment or investment.

Using a Metalworking Service

For those who do not require regular access to a metal lathe, utilizing metalworking services can be a viable option. Professional metalworking shops or services offer their expertise and equipment to complete machining tasks on your behalf. While this option may be more costly, it can save you time and effort in certain situations.

Joining a Makerspace

Consider joining a local makerspace or a community workshop that provides access to various tools and machinery, including metal lathes. Makerspaces often have shared equipment available for use by members, allowing you to indulge in metalworking projects without the need for large investments or dedicated workspace.

Factors to Consider When Choosing a Metal Lathe

When selecting a metal lathe, it is essential to consider specific factors to ensure it meets your requirements. Here are some crucial aspects to consider:

Size and Capacity

Evaluate the size of the workpieces you intend to work with and choose a lathe with appropriate swing and bed length capacities. Ensure that the lathe can handle the maximum size and weight of the workpieces you expect to work on to prevent limitations during your projects.

Power and Speed

Consider the horsepower and speed control options offered by the lathe. The power of the lathe’s motor determines the depth and speed at which it can cut through the material. Additionally, variable speed control allows you to adjust the cutting speed to suit different materials and operations.

Additional Features

Take into account any additional features that may enhance your metalworking experience. This could include digital readouts for precise measurements, quick-change tooling systems for efficiency, or threading capabilities for creating screw threads. Assess these features and determine their importance based on the specific projects you plan to undertake.

In conclusion, a metal lathe is a powerful and versatile tool that can greatly enhance your metalworking capabilities. It offers the benefits of versatility, precision, and cost-effectiveness. However, before purchasing a metal lathe, consider factors such as available space, budget, and frequency of use. Familiarize yourself with the different types of metal lathes to choose the one that best suits your needs. Remember to follow basic safety precautions, maintain your lathe properly, and seek learning opportunities to develop your lathe operational skills. Finally, if owning a metal lathe is not feasible, explore alternatives like renting or borrowing, using metalworking services, or joining a makerspace. By considering all these factors, you can make an informed decision and embark on exciting metalworking projects with confidence.