So you’ve encountered a stubborn screw that just won’t budge, and you’re left wondering if damaged screw extractors can actually save the day. We’ve all been there – frustrated and unsure of whether these tools are worth the investment. In this article, we’ll delve into the effectiveness of damaged screw extractors and reveal whether they truly live up to their reputation. Whether you’re a DIY enthusiast or a professional handyman, you won’t want to miss this insightful exploration of the realm of damaged screw extractors.

What are damaged screw extractors?

Damaged screw extractors are specialized tools designed to remove damaged or stripped screws from various materials such as wood, metal, or plastic. These extractors typically come in sets and are made from hardened steel, allowing them to withstand high torque and pressure. They are a valuable asset for individuals faced with the frustrating task of removing screws that have been damaged or stripped.

Types of damaged screw extractors

There are several types of damaged screw extractors available in the market. The most common ones include spiral flute extractors, double-ended extractors, and multi-flute extractors.

- Spiral flute extractors: These extractors feature special spiral flutes that grip into the damaged screw, allowing for easy extraction. They are available in different sizes to accommodate screws of various diameters.

- Double-ended extractors: These extractors have a unique double-ended design, allowing users to choose the appropriate end based on the screw’s size. They are ideal for situations where multiple screw sizes are involved.

- Multi-flute extractors: These extractors consist of multiple flutes or gripping threads. They provide a strong grip on the damaged screw and facilitate smooth extraction.

How do they work?

Damaged screw extractors work by using a reverse thread design to grip into the damaged screw surface. The extractors are first inserted into a pre-drilled hole or indentation made in the center of the damaged screw. This hole is typically made using a drill bit or a center punch.

Once the extractor is securely inserted, a wrench or a power drill is used to rotate the extractor counterclockwise. As the extractor turns, its reverse threads bite into the damaged screw, creating a firm grip. This grip allows the entire screw to be removed effortlessly without causing further damage to the surrounding material.

Factors to consider when using damaged screw extractors

When using damaged screw extractors, certain factors should be taken into consideration to ensure successful extraction. These factors include the size and type of the screw, the extent of the damage, the quality of the extractor, and the proper technique.

- Size and type of screw: It is important to select an extractor that matches the size and type of the damaged screw. Using the wrong size or type of extractor may result in unsuccessful extraction or further damage to the screw or material.

- Extent of damage: The extent of the damage to the screw plays a crucial role in determining which type of extractor to use. Minor damage may only require a single-flute extractor, while severely stripped screws may require a more aggressive multi-flute extractor.

- Quality of the extractor: Investing in a high-quality extractor set is essential for effective extraction. Cheap or low-quality extractors may break easily or fail to grip the screw properly, making the extraction process more challenging.

- Proper technique: Using the correct technique when using damaged screw extractors is crucial. It is important to apply steady pressure and ensure the extractor is securely fitted into the pre-drilled hole or indentation. Rushing or applying excessive force may lead to the extractor slipping or the screw getting further damaged.

Advantages of using damaged screw extractors

Using damaged screw extractors offers several advantages over alternative methods of screw removal. These advantages include time and effort savings, preservation of the material, and cost-effectiveness.

- Time and effort savings: Damaged screw extractors provide a quick and efficient solution to remove damaged or stripped screws. They eliminate the need for labor-intensive methods such as drilling or using excessive force with pliers, reducing the overall time and effort required for extraction.

- Preservation of the material: The reverse thread design of damaged screw extractors minimizes the risk of further damaging the surrounding material. The extraction process is smooth and controlled, preventing any unnecessary chipping, cracking, or scratching.

- Cost-effectiveness: Investing in a set of damaged screw extractors can be a cost-effective solution in the long run. Rather than replacing an entire piece of equipment or material due to a damaged screw, using an extractor allows for the repair or reuse of the existing components, saving both time and money.

Common challenges when using damaged screw extractors

Although damaged screw extractors are highly effective tools, certain challenges may arise during the extraction process. Understanding and addressing these challenges can help ensure successful screw removal.

- Limited success with severely damaged screws: In some cases, severely damaged or stripped screws may pose a challenge for extractors. The extreme level of damage may make it difficult for the extractor to gain a firm grip, resulting in unsuccessful extraction. In such cases, alternative methods may need to be considered.

- Potential damage to the surrounding material: While damaged screw extractors aim to minimize damage to the surrounding material, there is still a risk of slight damage or indentation. Vigilance and careful handling are important to minimize any unintended damage during the extraction process.

- Difficulty in accessing confined spaces: In situations where a damaged screw is located in a confined or hard-to-reach space, using a damaged screw extractor can be challenging. Limited space may restrict the movement and maneuverability of the extractor, requiring additional tools or techniques.

Steps to effectively use damaged screw extractors

To effectively use damaged screw extractors, it is important to follow a systematic approach. The following steps outline the process for successful screw extraction:

- Preparation: Start by preparing the damaged screw and surrounding area. Clean any debris or dirt around the screw to ensure a clear work surface.

- Securing the extractor: Select the appropriate damaged screw extractor from the set based on the size and type of the screw. Insert the extractor into a pre-drilled hole or indentation in the center of the damaged screw. Ensure the extractor is securely positioned.

- Rotating counterclockwise: Using a wrench or a power drill in reverse mode, begin rotating the extractor counterclockwise. Apply steady pressure and ensure the extractor remains securely engaged with the damaged screw.

- Additional techniques for stubborn screws: If the screw does not come out easily, additional techniques can be employed. These include applying heat using a heat gun, using penetrating oil to loosen the screw, or tapping it gently with a hammer to break any rust or corrosion bonds.

Alternatives to damaged screw extractors

While damaged screw extractors are highly effective, there are alternative methods to consider for screw removal. These alternatives can be used when extractors are not readily available or when facing certain challenges. The common alternatives include pliers or vise grip, drilling a hole, and using a screwdriver.

- Pliers or vise grip: If the damaged screw is not severely stripped, pliers or a vise grip can be used to grip and rotate the screw counterclockwise. This method requires a firm grip and careful maneuvering to avoid damaging the screw further.

- Drilling a hole: In situations where the damaged screw cannot be easily gripped, drilling a hole through the center of the screw can be an effective alternative. The hole allows for the use of a screwdriver or a specialized screw extractor to remove the screw.

- Using a screwdriver: If the damaged screw has minimal damage and can be gripped by a screwdriver, this traditional method can be employed. Apply firm downward pressure while turning the screw counterclockwise.

Situations where damaged screw extractors are most useful

Damaged screw extractors are invaluable tools in several situations and industries. The following are examples where damaged screw extractors are most commonly used:

- DIY projects: Whether you are working on furniture repairs, home renovations, or other DIY projects, damaged screw extractors can come to the rescue when faced with stripped or damaged screws. They make it possible to fix or replace components without having to resort to drastic measures.

- Woodworking: Woodworking projects often involve screws, and their extraction can be challenging due to the delicate nature of wood. Damaged screw extractors provide a controlled approach to removing damaged screws without causing further harm to the wood.

- Metalworking: In metalworking industries, screws and fasteners play a vital role. When screws get damaged or stripped, using damaged screw extractors allows for efficient removal, saving time and effort in the metal fabrication process.

- Repairing electronics: Electronics often have small, delicate screws that can be easily stripped or damaged. Using damaged screw extractors ensures precise and safe extraction, preventing the risk of further damage to expensive electronic components.

Reviews and opinions from users

Users of damaged screw extractors have shared their experiences, both positive and negative, regarding the effectiveness and usability of these tools. Here are some reviews and opinions from users:

Positive experiences:

- “I tried various methods to remove a stripped screw from a wooden cabinet, but it was the damaged screw extractor that finally did the job. It took a bit of time and patience, but it saved me from having to replace the entire cabinet door!”

- “I was skeptical at first, but the damaged screw extractor exceeded my expectations. It effortlessly removed several stripped screws from my old laptop, allowing me to upgrade its components without any hassle.”

Negative experiences:

- “I had limited success with a severely damaged screw using the extractor. It seemed like the screw was beyond repair, and I ended up having to drill it out completely.”

- “While the extractor did remove the damaged screw, it left a small indentation on the surface of the material. It’s not a major issue, but it would have been nice if the extractor had a protective coating.”

Tips and tricks from users:

- “For really stubborn screws, I found that using a soldering iron to heat up the screw slightly made it easier to loosen and extract.”

- “I always make sure to apply a penetrating oil to the damaged screw a few hours before attempting extraction. It significantly eases the process and reduces the risk of damage.”

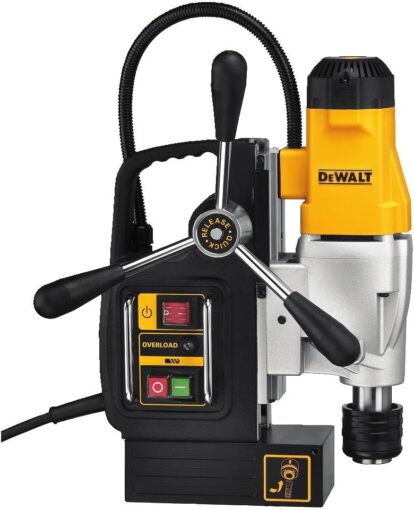

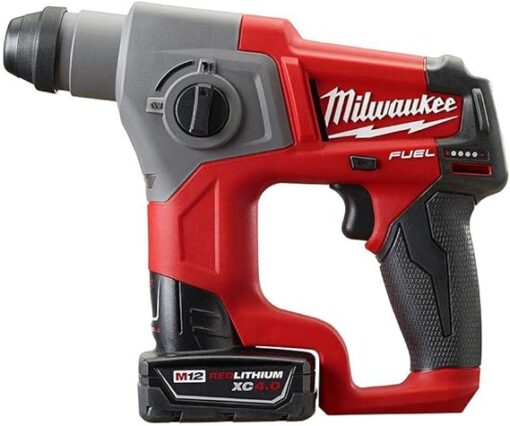

Common brands and models of damaged screw extractors

Several reputable brands offer high-quality damaged screw extractors. While there are numerous options available, this is our top choice.

Conclusion

Damaged screw extractors are highly effective tools for removing damaged or stripped screws from various materials. They offer a practical and efficient solution, saving time, effort, and money. When using damaged screw extractors, it is important to consider factors such as the size and type of the screw, the extent of the damage, the quality of the extractor, and proper technique. While challenges may arise, such as limited success with severely damaged screws or potential damage to the surrounding material, following the correct steps and using alternative techniques can help overcome these challenges. Damaged screw extractors find utility in various industries, such as DIY projects, woodworking, metalworking, and repairing electronics. User reviews and opinions provide valuable insight into their effectiveness, and common brands and models offer reliable options for those in need of a quality set of damaged screw extractors. Regardless of the situation, damaged screw extractors are an essential tool in any toolkit, providing a reliable solution for screw removal.