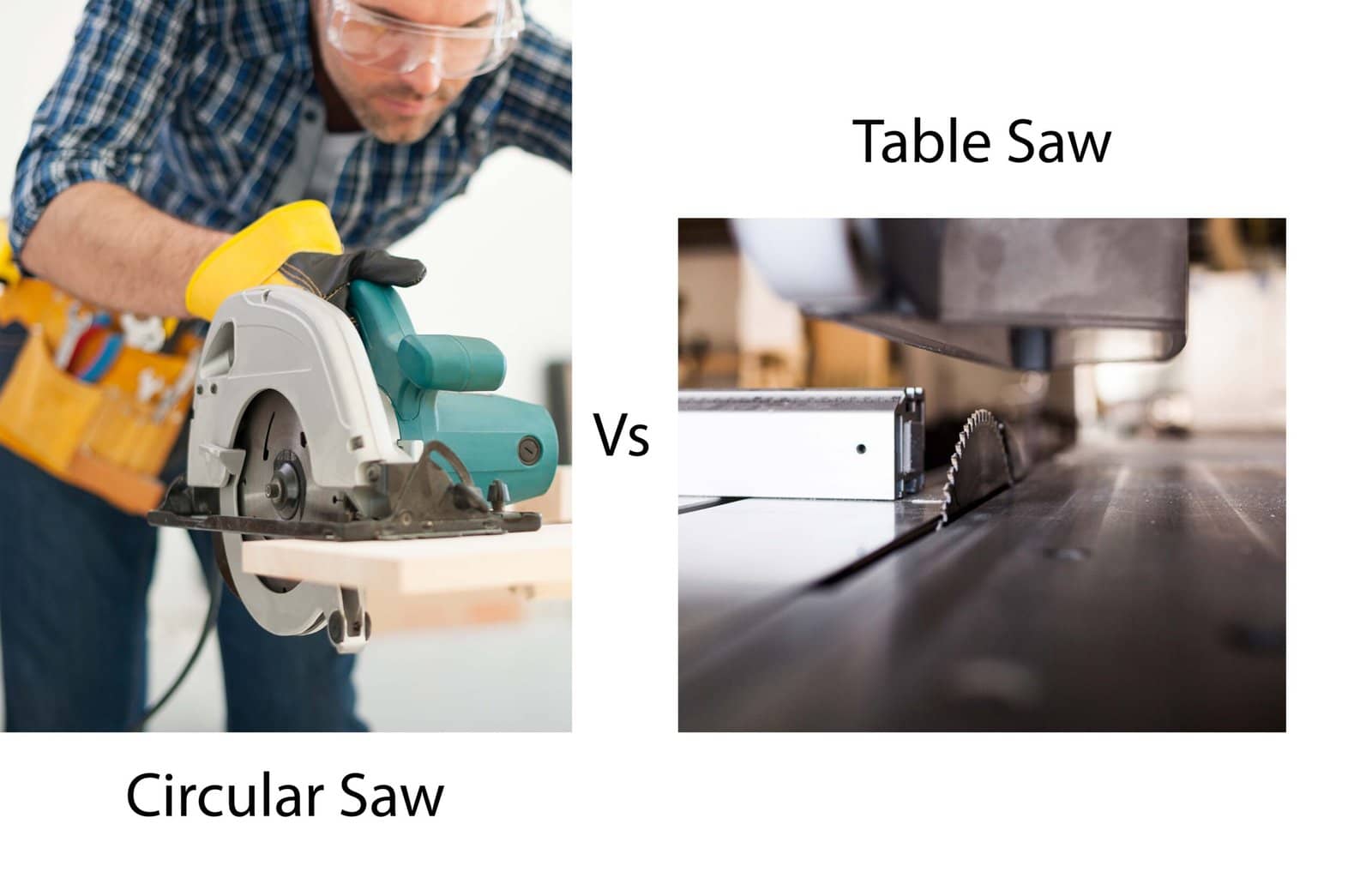

Have you ever found yourself torn between choosing a circular saw or a table saw for your woodworking projects? Making a decision can be overwhelming, especially when both tools offer unique features and benefits. In this article, we will explore the differences and similarities between circular saws and table saws, helping you determine whether you should invest in one or both. With insights and recommendations, you’ll be on your way to making informed choices that will enhance your woodworking experience.

Circular Saw

Advantages of a Circular Saw

A circular saw is a versatile and powerful cutting tool that has several advantages. Firstly, its compact and handheld design allows for easy maneuverability, making it ideal for both professional contractors and DIY enthusiasts. With a circular saw, you can tackle a variety of cutting tasks, from straight cuts to bevel cuts and even plunge cuts.

Secondly, circular saws are extremely efficient and can make quick work of cutting through a wide range of materials, including wood, metal, plastic, and even masonry. This versatility makes them indispensable in woodworking projects as well as construction and renovation work.

Another advantage of a circular saw is its portability. Unlike larger stationary tools such as a table saw, a circular saw can be easily transported to different job sites, allowing you to work wherever the project takes you. This flexibility is particularly useful for professionals who often need to move between locations.

Disadvantages of a Circular Saw

While the circular saw offers numerous advantages, there are also some drawbacks to consider. One of the main disadvantages is the lack of precision compared to a table saw. The handheld nature of a circular saw can make it challenging to achieve perfectly straight cuts, especially for those new to using the tool. This can result in wasted material and the need for additional finishing work.

Furthermore, although circular saws are versatile, they may not be suitable for certain specialized cutting tasks. For example, intricate and delicate work, such as cutting intricate designs or creating precise joints, is better suited for a table saw or other more precise cutting tools. Additionally, circular saws may not provide the same level of accuracy and repeatability as table saws, which can be crucial for complex projects or when working with expensive materials.

Types of Circular Saws

Circular saws are available in various types, each designed to meet specific cutting needs. The most common types include:

- Sidewinder Circular Saw: This type of circular saw features a motor mounted alongside the blade, making it more compact and lightweight. Sidewinder circular saws are suitable for general-purpose cutting tasks and are popular among DIYers.

- Worm Drive Circular Saw: Worm drive circular saws have the motor placed behind the blade, providing more torque and power. This makes them ideal for heavy-duty tasks, such as cutting through thick lumber or dense materials.

- Track Saw: Track saws, also known as plunge-cut saws, are designed for precise and straight cuts. They feature a guide rail system that ensures accurate cuts and reduces the risk of splintering. Track saws are commonly used in cabinetry and furniture making.

- Mini Circular Saw: As the name suggests, mini circular saws are compact and lightweight versions of the traditional circular saw. They are ideal for small-scale projects, tight spaces, or when working with smaller materials.

Key Features to Consider

When choosing a circular saw, there are several key features to consider to ensure you select the right tool for your needs:

- Power: The power of the motor will determine the saw’s cutting capacity and efficiency. Higher-powered motors are generally better for heavy-duty tasks, while lower-powered ones may be more suitable for lighter projects.

- Blade Size: Circular saws are available in different blade sizes, typically ranging from 4.5 to 7.25 inches. Consider the type of materials you will be cutting and select a blade size accordingly.

- Bevel Capacity: The ability to make bevel cuts allows you to create angled edges. Check the bevel capacity of the circular saw and ensure it meets the requirements of your projects.

- Cutting Depth and Adjustability: The maximum cutting depth of the saw is essential, as it determines the thickness of material that can be cut. Additionally, look for a circular saw with easy depth adjustment for added convenience.

- Safety Features: Pay attention to safety features, such as blade guards and a reliable anti-kickback system, to ensure safe operation.

Choosing the Right Circular Saw

To choose the right circular saw, you need to consider your specific cutting needs, skill level, and budget. If you are a DIYer or occasional woodworker working on small to medium-sized projects, a sidewinder circular saw would be a suitable choice. Its affordability and versatility make it a popular option among beginners.

For more heavy-duty tasks or professional use, a worm drive circular saw offers more power and durability. This type of circular saw can handle cutting through thicker and denser materials with ease.

If precise cuts and accuracy are crucial, a track saw may be the best option. Although slightly more expensive, the guide rail system ensures smooth and accurate cuts, making it ideal for cabinet-making and other detailed woodworking projects.

Ultimately, it is important to choose a circular saw that matches your needs, skill level, and budget to get the most out of this versatile cutting tool.

Table Saw

Advantages of a Table Saw

A table saw is a stationary woodworking tool that offers its own set of advantages. The primary advantage of a table saw is its ability to make precise and straight cuts consistently. The stationary table and adjustable rip fence provide stability and accuracy, allowing for repeatable cuts with minimal effort.

Furthermore, the larger surface area of the table saw’s work surface provides support and stability for cutting larger or heavier materials. This makes it easier to handle large plywood sheets, longboards, or other bulky materials that may be difficult to manage with a circular saw.

In addition to handling larger materials, a table saw excels at making various types of cuts, including crosscuts, rip cuts, bevel cuts, and even complex joinery cuts. This versatility makes it a go-to tool for professional woodworkers and craftsmen who require precise and intricate cuts in their projects.

Disadvantages of a Table Saw

Despite its many advantages, a table saw also has certain disadvantages to consider. The primary drawback is its size and immobility. Table saws are large and often require a dedicated space in a workshop or garage. They are not portable like circular saws, which can limit their use to a specific location.

Furthermore, the cost of a table saw can be prohibitive for some. Quality table saws with advanced features can be quite expensive compared to circular saws, making them more suitable for serious woodworking enthusiasts or professionals who will make frequent use of their capabilities.

Lastly, the learning curve for using a table saw effectively and safely can be steep. It requires proper technique, knowledge of different cuts, and careful attention to safety precautions. Beginners may need to invest additional time to develop these skills and confidence in operating a table saw.

Types of Table Saws

Table saws come in different types to cater to various woodworking needs. The common types include:

- Contractor Table Saw: Contractor table saws strike a balance between portability and power. While they are relatively lightweight and can be transported to different job sites, they still offer sufficient power for most woodworking tasks.

- Cabinet Table Saw: Cabinet table saws are heavy-duty machines designed for professional use and large-scale projects. They are durable, powerful, and provide exceptional precision, making them a top choice for serious woodworkers.

- Hybrid Table Saw: Hybrid table saws combine elements of contractor and cabinet saws. They offer portability and affordability similar to contractor saws, along with some of the advanced features and power of cabinet saws.

- Benchtop Table Saw: Benchtop table saws are compact and lightweight, allowing for easy placement on a workbench or table. They are ideal for smaller projects or for those with limited workspace.

Key Features to Consider

When selecting a table saw, several key features should be considered to ensure you choose the right tool for your woodworking needs:

- Motor Power: The motor power will determine how easily the table saw cuts through different materials. Higher horsepower motors are typically better for heavy-duty tasks or working with dense woods.

- **Table Size and Extension: **Consider the size of the table and whether it has extension wings to accommodate larger workpieces. The larger the table, the more stability it provides for cutting larger materials.

- Fence Quality: The fence is an essential component for accurate and precise cuts. Look for a table saw with a sturdy and adjustable fence system that locks securely in place.

- Blade Adjustability: Consider how easily and accurately you can adjust the blade height and angle. Quick and precise adjustments are crucial for achieving the desired cuts.

- Safety Features: Look for a table saw with safety features such as blade guards, anti-kickback pawls, and a reliable emergency stop mechanism to ensure safe operation.

Choosing the Right Table Saw

Choosing the right table saw depends on several factors, including your level of woodworking expertise, the size of projects you typically tackle, and your budget.

For beginners or DIYers with limited workspace, a benchtop or contractor table saw would be a suitable choice. They are more affordable and offer good performance for smaller-scale projects.

For serious woodworkers or professionals who require precision and power, a cabinet saw or hybrid table saw is the way to go. They provide exceptional accuracy, durability, and power, making them suitable for large-scale projects.

Ultimately, consider your budget, available space, and the type of woodworking projects you undertake to determine the most suitable table saw for your needs.

Using Both Circular Saw and Table Saw

Benefits of Using Both Tools

While each tool has its strengths, there are significant benefits to using both a circular saw and a table saw in your woodworking projects.

By combining the cutting capabilities of both tools, you can enjoy the advantages of versatility and precision. The circular saw allows for portability and the ability to make rough cuts quickly, while the table saw excels in providing accurate and repeatable cuts.

Another benefit of using both tools is increased productivity. Instead of solely relying on one tool to complete all tasks, having both a circular saw and a table saw allows you to work more efficiently. You can utilize the circular saw for initial cuts or rough sizing of materials, and then use the table saw for fine-tuning and precise cuts.

Safety Considerations

When using both a circular saw and a table saw in combination, it is crucial to prioritize safety. Both tools can cause serious injuries if not used properly. Here are some safety considerations to keep in mind:

- Proper Protective Gear: Always wear safety goggles, ear protection, and appropriate clothing when operating power tools. Gloves can also provide added protection.

- Secure Workpieces: Ensure that the workpieces are secure and stable before making any cuts. Unstable or loose materials can lead to accidents or inaccurate cuts.

- Sharp Blades: Keep the blades of both the circular saw and table saw sharp. Dull blades can result in kickback or excessive force, posing a safety hazard.

- Follow Manufacturer Guidelines: Familiarize yourself with the user manuals and safety guidelines for both tools. Adhere to the recommended operating procedures and safety precautions.

- Proper Handling and Storage: When not in use, store the tools in a secure place, out of reach from children and unauthorized users. Handle the tools with care, ensuring they are turned off and unplugged when making adjustments or changing blades.

Combining Techniques

Using both a circular saw and a table saw allows you to employ various woodworking techniques and achieve the best possible results in your projects.

For example, you can utilize the circular saw for making long rip cuts on large plywood sheets or cutting rough stock to a manageable size. Once initial cuts are made, the table saw can be used for precise crosscuts, bevel cuts, or creating intricate joinery, thanks to its stability and accuracy.

By combining techniques, you can tackle a wide range of projects with greater efficiency and versatility. From building furniture to constructing cabinets or even crafting detailed woodworking pieces, having both tools in your arsenal enhances your woodworking capabilities.

In conclusion, both circular saws and table saws have their advantages and disadvantages, and the choice ultimately depends on your specific needs, budget, and level of expertise. While a circular saw offers portability and versatility, a table saw excels in accuracy and the ability to handle larger materials. However, using both tools together provides the best of both worlds – quick rough cuts, portability, and precise finishing. Just remember to prioritize safety, follow proper operating procedures, and select the right tools for each task to enhance your woodworking experience. Happy cutting!