So, you’ve been contemplating whether SDS drills are a good fit for your DIY adventures at home. Well, fear not, because in this article, we’ll explore the question of whether SDS drills are suitable for use in a household setting. From their features and functionality to their ease of use and safety considerations, we’ll provide you with all the information you need to make an informed decision. Whether you’re a seasoned DIY enthusiast or just starting out, we’ve got you covered. Let’s dive into the world of SDS drills and discover if they’re the perfect match for your home projects and who might use one.

Safety Considerations

When it comes to using any power tool, including SDS drills, safety should always be the top priority. Understanding the basics of SDS drills and taking appropriate safety measures is crucial to ensure your well-being and the success of your projects.

Understanding the Basics of SDS Drills

SDS drills, also known as Special Direct System drills, are specifically designed for drilling into masonry and concrete. They feature a unique chuck system that allows for quick and easy bit changes. The SDS chuck holds the bit securely in place, preventing slippage and providing efficient power transfer during drilling. It is important to familiarize yourself with the different types of SDS drills to understand their capabilities and limitations.

Safety Measures for Using SDS Drills

Before you start using an SDS drill, there are a few safety measures you should always follow. First and foremost, wear appropriate protective gear, such as safety glasses, gloves, and ear protection, to safeguard yourself against flying debris, vibrations, and noise. Secondly, ensure that the drill is properly plugged into a grounded outlet or that the battery is fully charged for cordless models. Lastly, be mindful of your surroundings and keep a clear workspace to minimize the risk of accidents.

Importance of Protective Gear

Protective gear plays a significant role in ensuring your safety while using SDS drills. Safety glasses help protect your eyes from flying debris, while gloves provide a firm grip and reduce the risk of cuts or blisters. Additionally, wearing ear protection, such as earmuffs or earplugs, is essential to guard against the loud noise produced by the drill. By investing in and wearing proper protective gear, you can greatly reduce the chances of injury and work comfortably with your SDS drill.

Precautions to Take While Operating SDS Drills at Home

While SDS drills are versatile and convenient for various home projects, it is important to exercise caution during their operation. Always ensure that you have a firm grip on the drill, using both hands to maintain control. Avoid wearing loose clothing or jewelry that may get caught in the drill. Additionally, be cautious of any cords, ensuring they are not in your way or at risk of becoming tangled during use. By taking these precautions, you can greatly minimize the risk of accidents or injuries while operating an SDS drill at home.

Types of SDS Drills

SDS drills come in different types, each designed for specific applications and varying levels of power. Understanding the differences between these types can help you choose the most suitable SDS drill for your projects at home.

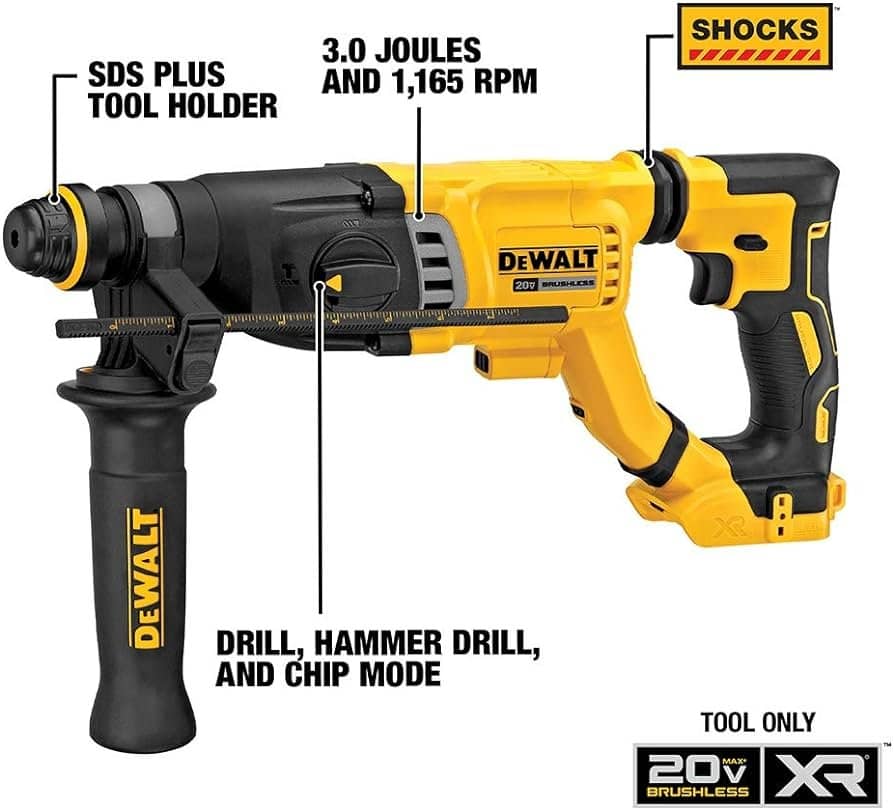

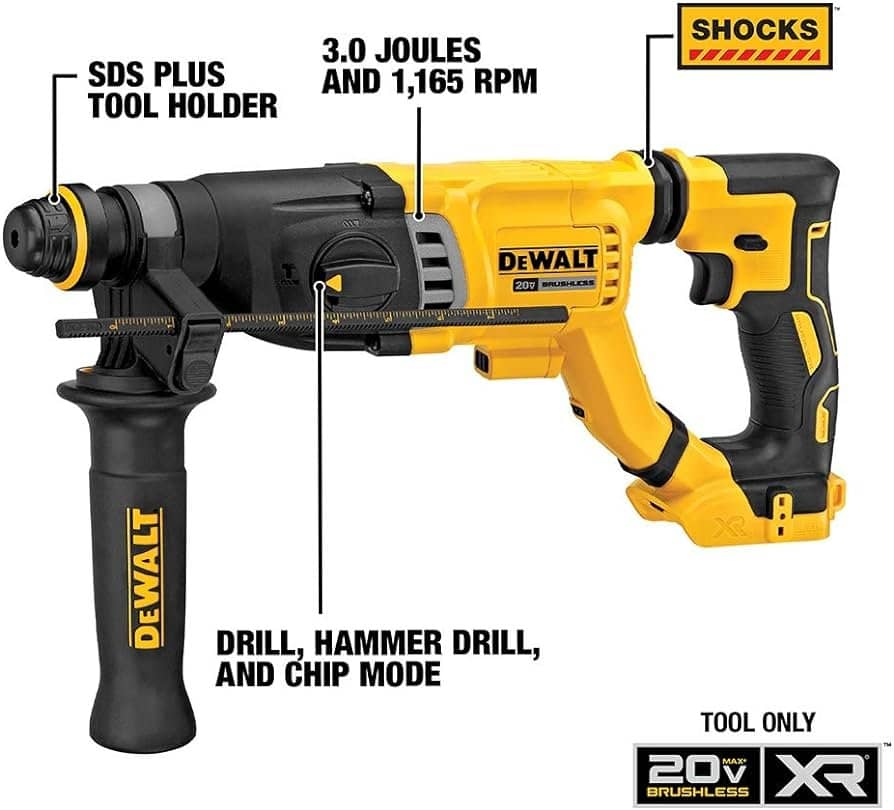

SDS Plus Drills

SDS Plus drills are the most commonly used type of SDS drill for general home use. They offer a good balance of power, speed, and versatility, making them suitable for a wide range of projects. SDS Plus drills are designed for drilling into masonry, concrete, and other hard materials, making them ideal for tasks such as installing shelves, building cabinets, or hanging wall decorations.

SDS Max Drills

SDS Max drills are heavy-duty SDS drills that provide exceptional power and capability. They are commonly used for professional and heavy-duty applications, such as drilling large diameter holes or breaking up concrete. While SDS Max drills offer immense power, they are generally not necessary for typical home DIY projects unless you plan on tackling exceptionally challenging tasks.

Applications of SDS Drills at Home

SDS drills are incredibly versatile tools that can be used for a wide range of projects around the house. Here are some common applications where SDS drills excel:

Drilling into Masonry and Concrete

One of the primary purposes of SDS drills is drilling into masonry and concrete. Whether you’re installing anchors, creating holes for pipes or wires, or adding hooks for hanging items, SDS drills provide the necessary power and efficiency to get the job done quickly and effectively.

Installing Bathroom Fixtures

When it comes to installing bathroom fixtures, such as towel racks, toilet paper holders, or shower curtain rods, SDS drills make the process much easier. Their ability to drill into tile and other hard surfaces makes them indispensable for these types of installations. Plus, with the quick and easy bit changes offered by SDS drills, you can switch between drilling holes and driving screws without hassle.

Building Shelves and Cabinets

If you enjoy woodworking or DIY furniture projects, SDS drills can be a valuable asset. Whether you’re building shelves, cabinets, or other wooden structures, SDS drills can assist in drilling holes for dowels, screws, or other fasteners. The power and precision of an SDS drill make it a reliable tool for ensuring sturdy joints and accurate measurements.

Hanging Wall Decorations

When it comes to hanging wall decorations like picture frames, mirrors, or shelves, SDS drills can save you time and effort. With their ability to drill into various wall materials, including plaster and drywall, SDS drills make the installation process much smoother. Plus, the hammer action of SDS drills helps create secure and stable anchor points, ensuring your decorations stay in place.

Fencing and Decking Projects

Whether you’re building a new fence or constructing a deck, SDS drills can make the process easier and more efficient. With their capability to drill through wood, metal, and concrete, SDS drills can handle the various materials involved in these outdoor projects. From drilling post holes to attaching brackets or connectors, SDS drills provide the necessary power and flexibility to tackle these demanding tasks.

Advantages of SDS Drills for Home Use

When considering the use of SDS drills for your home projects, it’s important to understand the advantages they offer over other types of drills.

Powerful and Efficient Drilling

SDS drills are specifically designed for drilling into hard materials such as masonry and concrete. Compared to regular drills, SDS drills offer more power and efficiency, allowing you to drill faster and with less effort. This advantage is especially beneficial for challenging home projects that require drilling into tough surfaces.

Ease of Use

Another advantage of SDS drills is their user-friendly design. The SDS chuck system makes it incredibly easy to change drill bits quickly, without the need for additional tools or manual tightening. This feature saves time and frustration, allowing you to switch between different types of bits seamlessly. Additionally, the ergonomic handles and grips of SDS drills make them comfortable to use for extended periods, reducing fatigue and increasing productivity.

Versatile Functionality

SDS drills are highly versatile tools, capable of performing a wide range of tasks. With the appropriate drill bits, you can drill holes of various sizes, install anchors, drive screws, and even chisel or break up concrete using the hammer function. The versatility of SDS drills eliminates the need for multiple tools, saving you both time and storage space.

Quick and Easy Bit Changes

One of the standout features of SDS drills is their ability to change drill bits quickly and easily. The SDS chuck system allows for effortless bit insertion and removal, without the need for additional tools or loosening/tightening mechanisms. This feature is a major time-saver, as it eliminates the frustration of struggling with traditional chucks or keyless chuck systems.

Limitations of SDS Drills for Home Use

While SDS drills offer numerous advantages, it’s important to consider their limitations before deciding if they are suitable for your home projects.

Cost

Compared to regular drills, SDS drills tend to be more expensive due to their specialized chuck system and enhanced drilling capabilities. If you’re on a tight budget or only plan on using a drill for occasional DIY tasks, the cost of an SDS drill may be prohibitive. In such cases, a more affordable alternative may be a corded or cordless drill, depending on your needs.

Size and Weight

SDS drills are generally larger and heavier than regular drills due to their design and increased power output. While this robust construction contributes to their efficiency and effectiveness, it may be a drawback for some users. If you have limited storage space or struggle with heavy tools, the size and weight of an SDS drill may be a consideration to keep in mind.

Noise and Vibration

Due to their powerful motors and hammer action, SDS drills can produce significant noise and vibrations during operation. This can be problematic, especially if you live in a noise-sensitive environment or have neighbors in close proximity. While wearing ear protection and using proper drilling techniques can help mitigate the noise and vibrations, it’s important to consider this factor before deciding on an SDS drill for home use.

Overkill for Light DIY Tasks

If your DIY projects primarily involve light tasks such as hanging pictures, assembling furniture, or drilling into soft materials like wood or drywall, an SDS drill may be overkill. The high power and hammer action of an SDS drill are best suited for challenging applications, and using it for simple tasks may not be necessary. In such cases, a regular corded or cordless drill may be a more practical and cost-effective choice.

Choosing the Right SDS Drill

Selecting the right SDS drill for your home projects requires careful consideration of several factors.

Consideration of Project Requirements

Start by assessing the specific requirements of your projects. Consider the materials you’ll be drilling into, the sizes of the holes you’ll need, and the overall scope and complexity of your tasks. This evaluation will help you determine the necessary power, drilling capacity, and features required in an SDS drill.

Power and Performance

Choosing an SDS drill with the appropriate power and performance capabilities is crucial for successful home projects. Consider the drill’s voltage, amperage, and impact energy to ensure it can handle the materials and tasks you’ll be working with. Higher voltage and impact energy generally indicate more power and drilling ability.

Ergonomics and Handling

Since you’ll be using the SDS drill for extended periods, it’s important to select one that offers comfortable handling and ergonomic features. Look for drills with rubberized grips, adjustable handles, and low vibration levels to minimize fatigue and improve user comfort.

Budget Constraints

While SDS drills can be more expensive than regular drills, it’s important to consider your budget limitations when making a purchase. Determine a realistic budget and seek out models that offer the necessary features and capabilities within your price range. It’s important to strike a balance between affordability and functionality.

Maintenance and Care for SDS Drills

Proper maintenance and care are essential for prolonging the life and performance of your SDS drill. By following these guidelines, you can ensure that your drill remains in optimal condition for years to come.

Cleaning the Drill and Accessories

Regularly clean your SDS drill and its accessories to remove dust, debris, and other particles that may affect its performance. Use a soft brush or compressed air to clean the drill body, chuck, and vents. Wipe down the drill with a clean, damp cloth to remove any remaining residue. When cleaning the drill bits, use a wire brush or a specialized bit cleaner to remove built-up debris.

Regular Lubrication

Lubricating your SDS drill is essential for maintaining its smooth operation. Apply a small amount of grease or lubricating oil to the drill chuck and internal parts as recommended by the manufacturer. This will help reduce friction, prevent rust, and extend the life of your drill.

Storage and Protection

When not in use, store your SDS drill in a clean and dry location, away from moisture and extreme temperatures. Consider using a case or storage box specifically designed for drills to provide added protection. Additionally, always remove the drill bit from the chuck when storing the drill, as leaving it inserted may cause unnecessary strain on the chuck and decrease its lifespan.

Alternatives to SDS Drills for Home Use

While SDS drills offer many advantages, they may not be the ideal choice for every home project. Consider these alternative drill types depending on your specific needs.

Corded Drills

Corded drills are a reliable and cost-effective option for most home projects. They offer sufficient power and versatility for drilling through various materials, such as wood, plastic, and metal. Corded drills are generally lightweight and compact, making them easy to handle and store. However, keep in mind that they require a power outlet nearby and may limit mobility compared to cordless models.

Cordless Drills

Cordless drills provide the flexibility and convenience of on-the-go drilling without the need for a power source. They are powered by rechargeable batteries, offering mobility and ease of use. Cordless drills are available in different voltages, allowing you to choose a model that suits your power requirements. However, bear in mind that cordless drills may have limitations regarding power and continuous runtime, especially when tackling more demanding drilling tasks.

Hammer Drills

Hammer drills are another alternative to SDS drills that can be suitable for certain home projects. They combine the functions of a regular drill with a hammer action, allowing for drilling into masonry and concrete. Hammer drills are generally less powerful and less expensive than SDS drills, making them a viable option for smaller-scale tasks. However, they may not provide the same level of efficiency and ease of use as SDS drills when dealing with tougher materials.

Tips for Safe and Effective SDS Drill Usage

To ensure safe and effective use of your SDS drill, follow these tips:

Read and Follow the Manufacturer’s Instructions

Always thoroughly read and understand the manufacturer’s instructions for your specific SDS drill model. Familiarize yourself with the drill’s features, operation, maintenance requirements, and safety guidelines. Following the manufacturer’s instructions will help prevent accidents and maximize the performance of your SDS drill.

Secure Your Workpiece

Before drilling, ensure that your workpiece is securely clamped or held in place to prevent it from moving or spinning during drilling. This will enhance your control over the drill and minimize the risk of errors or accidents. It is also important to have a stable and level work surface to work on.

Use Proper Speed and Pressure

To achieve optimal drilling results, it is essential to use the correct speed and pressure. Consult the manufacturer’s guidelines for recommended drilling speeds and select the appropriate gear setting on your drill. Apply steady and consistent pressure while drilling, allowing the drill bit to do the work without forcing it. Applying excessive pressure may cause the bit to bind or break.

Take Breaks for Cooling

SDS drills generate heat during prolonged use, which can affect their performance and potentially damage internal components. To prevent overheating, take regular breaks while drilling to allow the drill and motor to cool down. This is especially important when working with demanding materials or for extended periods. If you notice the drill becoming excessively hot, stop drilling and let it cool down before continuing.

Inspect and Replace Worn-out Parts

Regularly inspect your SDS drill for signs of wear or damage. Check the power cord or battery connections, chuck, and handle for any cracks, fraying, or other defects. If you notice any issues, immediately stop using the drill and have it repaired or replaced, if necessary. Worn-out or damaged parts can compromise the drill’s safety and performance.

Dispose of Batteries Safely

If you are using a cordless SDS drill, it is important to dispose of its batteries safely. Rechargeable batteries can be recycled, and many retailers and recycling centers offer battery disposal services. Avoid throwing batteries in the trash or incinerating them, as they can contain harmful substances that are detrimental to the environment.

Conclusion

When it comes to choosing the right drill for your home projects, considering the advantages, limitations, and safety aspects of SDS drills is essential. By understanding the basics of SDS drills, the applications they excel in, and the precautions necessary for their safe operation, you can make an informed decision. Evaluate your project requirements, budget constraints, and personal comfort to determine if an SDS drill is suitable for your DIY endeavors. Remember to prioritize safety, properly maintain your SDS drill, and explore alternative drill options when necessary. With careful consideration and the right tool at your disposal, you can confidently tackle a wide range of home projects with ease and precision.